دکتر لاله کدیور - Insights Into Technical Drawings

Sometimes, when we think about innovation and making things, our minds go straight to the big ideas, the grand designs, or perhaps the people behind them. But, you know, what truly brings these concepts to life often lies in the very small, precise details. It's in the careful measurements, the specific symbols on a drawing, and the way every single piece is meant to fit together. This kind of work, it really is the foundation for so much of what we use and experience every day, from the simplest gadget to the most complex machinery.

There's a whole language spoken in the world of creating physical objects, a language of lines, numbers, and symbols that tells a complete story about how something should be built. It's a precise way of talking, one that leaves very little room for guesswork, and that's pretty important when you're trying to make sure parts fit just right or a machine works as it should. This language, it's a bit like a secret code for those who know how to read it, but it’s actually incredibly logical once you get the hang of it.

We're going to take a look at some of these very specific technical ideas and how they play a part in bringing designs from a thought to something you can actually hold. While we might be thinking about someone like دکتر لاله کدیور, and the kind of contributions a person like that might make in fields that rely on such exactness, our focus here will be on breaking down the nuts and bolts of what these drawings tell us. It’s about making sense of the details that help turn an idea into a tangible item.

- Paleseafoam Leaks Of

- Ralph Macchio Net Worth

- As The World Caves In Song Meaning

- Houses For Sale In Iran

- Was The Shah Of Iran A Good Leader

Table of Contents

- Who is دکتر لاله کدیور? - A Look at Engineering Insights

- What Do Those Symbols Really Mean? - Deciphering Technical Language for دکتر لاله کدیور

- How Do We Pinpoint Dimensions? - Precision in Drawings for دکتر لاله کدیور

- What About the Parts? - Practical Applications for دکتر لاله کدیور

- How Do We Make Things? - From Design to Production with دکتر لاله کدیور

- Why Is Precision So Important? - The Role of Tolerancing for دکتر لاله کدیور

- Where Does This Knowledge Come From? - Learning and Practice for دکتر لاله کدیور

- What's Next in Technical Design? - Future Considerations for دکتر لاله کدیور

Who is دکتر لاله کدیور? - A Look at Engineering Insights

When we talk about individuals who contribute to fields that shape our world, like engineering or product creation, we often imagine someone with a strong grasp of technical details. While we don't have specific personal details about دکتر لاله کدیور from the information provided, we can certainly explore the kinds of technical insights that would be valuable to someone working in areas where precision and clear communication are key. It’s about the foundational knowledge that lets people bring complex ideas into physical reality, which is, in a way, what a lot of engineering is all about.

The information we have at hand speaks to the very specific language used in mechanical drawings and design, which is a big part of creating anything from a simple component to an entire machine. This kind of work involves a deep familiarity with symbols, measurements, and manufacturing processes. So, while we can't tell you about دکتر لاله کدیور's personal life, we can talk about the world of technical design that someone with that title might engage with. It's a field that asks for a sharp eye and a very clear way of thinking about how things are put together.

For someone involved in making things, whether it's for a custom 3D printer or a larger industrial project, understanding how to read and create these drawings is pretty much essential. It’s like having the blueprint for a building; you need to know what each line and number means. This knowledge helps make sure that what’s drawn on paper turns into a physical object exactly as intended. It's a skill that, you know, makes a real difference in how successful a project turns out.

- What Does The Term Eiffel Tower Mean

- Desmond Doss The Unyielding Spirit Of A Conscientious Objector

- Iran And Pakistan Map

- From Champion To Inspiration Ronnie Coleman Now

- Dafina Miftari

| Category | Information |

|---|---|

| Full Name | دکتر لاله کدیور (Dr. Laleh Kadiour) |

| Primary Field | Likely Mechanical Engineering, Product Design, or Manufacturing (Information not available from provided text) |

| Key Skills | Interpreting Technical Drawings, CAD Software Use, Understanding Manufacturing Processes, Precision Measurement (Inferred from provided text) |

| Associated Technologies | Stepper Motors, Resistors, CNC Machining, 3D Printing (Inferred from provided text) |

| Role in Industry | Likely involved in design, development, or quality control of physical products (Information not available from provided text) |

What Do Those Symbols Really Mean? - Deciphering Technical Language for دکتر لاله کدیور

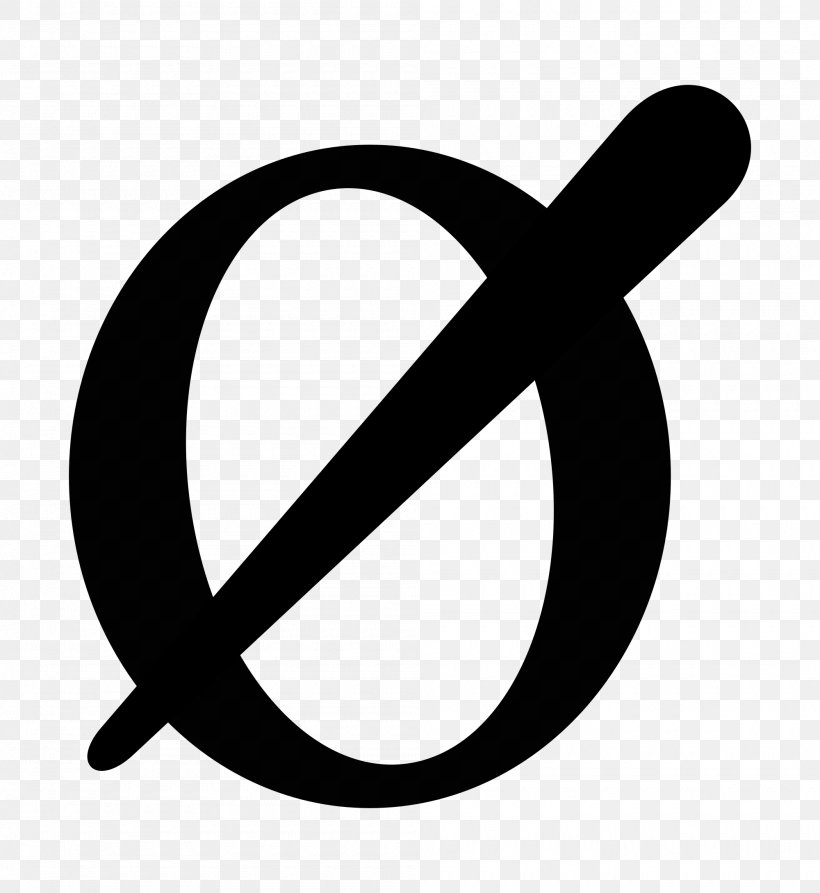

When you look at a technical drawing, you'll often see symbols that might seem a little mysterious at first glance. Take, for instance, the little circle with a diagonal line through it, like 'ø', or sometimes a similar one, 'φ', and even the official diameter symbol '⌀'. These aren't just decorative marks; they're, you know, a very specific way of telling you about the size of something round. They're typically used to show the measurement across a circle or a cylindrical part, which is pretty important for making sure things fit together.

For example, if you see 'ø6' on a datasheet for something like a stepper motor, that 'ø' is pretty much saying, "Hey, this part's diameter is 6 millimeters." This is a quick and clear way to communicate a crucial dimension without needing a lot of words. It’s like a shorthand that everyone in the field understands, which, you know, saves a lot of time and prevents mistakes. The fact that the diameter symbol (⌀) looks a lot like the lowercase letter ø in some fonts can be a bit confusing, but they serve the same purpose in technical drawings.

The importance of these symbols really comes into play when you're dealing with components that need to connect perfectly, like a shaft going into a hole. Knowing the exact diameter, thanks to these clear symbols, helps ensure that the parts won't be too loose or too tight. It's a bit like picking the right size screw for a specific hole; you need to know the diameter to get it right. So, for someone like دکتر لاله کدیور, understanding these basic symbols is a foundational step in making sense of any design document.

How Do We Pinpoint Dimensions? - Precision in Drawings for دکتر لاله کدیور

Beyond just the diameter symbols, technical drawings have other specific ways to show measurements and how they apply. You might see something like '4x' next to a dimension. This is a simple, yet very effective, way to tell you that a particular feature, like a hole or a specific shape, appears four times on the drawing and has the same measurement. It saves space and makes the drawing less cluttered, which is, you know, pretty helpful when you're looking at a complex design.

Then there are phrases like 'thru all' or 'through all'. When this is added to a dimension for a hole, it means that the hole goes completely through the entire thickness of the part. It's not just a partial drill or a blind hole; it goes all the way through. This is a really important instruction for anyone who is actually making the part, because it tells them exactly how deep to drill. It’s a very clear instruction that, you know, leaves no room for guessing, which is pretty much what you want in manufacturing.

Sometimes, you'll see measurements that combine symbols and letters, like 'ø12 x 25L'. We know the 'ø12' means a 12-millimeter diameter, but what about the 'x25L'? This often indicates a length or a specific feature related to that diameter. For example, it might mean the hole is 12 millimeters in diameter and 25 millimeters long. Or, it could refer to a specific type of fitting or a standard part where 'L' stands for length. These combined notations help give a complete picture of a part's geometry, which is, so, very useful for anyone like دکتر لاله کدیور who might be working on detailed schematics for things like plastic pieces.

Other annotations, like 'R1.25 typ' or '2xø1.0', also provide crucial information. 'R1.25 typ' means a radius of 1.25 millimeters, and 'typ' stands for "typical," suggesting that this radius applies to similar features unless stated otherwise. '2xø1.0' means there are two holes, each with a diameter of 1.0 millimeters. These kinds of notes are, you know, the building blocks for accurately understanding what a part is supposed to look like and how it's supposed to function. They really are the language of precision.

What About the Parts? - Practical Applications for دکتر لاله کدیور

The technical drawings we've been discussing aren't just abstract concepts; they apply to very real, tangible parts that make up our machines and devices. Think about a stepper motor, for example. These motors are used in all sorts of things, from 3D printers to robotics, because they can move in very precise steps. The data sheet for such a motor would list specific dimensions, like the 'ø6' for the pinion's pitch diameter. This measurement is, so, important because it affects how the motor connects to other gears and how accurately it can move something.

Or consider something as common as a resistor, a small electronic component that controls the flow of electricity. On a technical drawing for resistors, you might see the 'φ0.55mm' for the lead diameter. The lead is the wire that sticks out of the resistor, allowing it to be connected to a circuit. Knowing this diameter is pretty important for manufacturing, especially when you're dealing with specific wire gauges like '24 swg', which is a standard way of measuring wire thickness. It’s all about making sure the parts are, you know, made to the right size so they can do their job properly.

The same level of detail applies to more complex shapes, like a plastic piece with an oval hole. Understanding the different parts of a measurement, such as the diameter and then an additional length or feature notation, is key to correctly modeling or manufacturing that piece. It’s not just about the big picture; it’s about every curve, every hole, and every edge being exactly as it should be. This kind of exactness is, you know, what allows everything to fit together and work smoothly, which is very important in product development for someone like دکتر لاله کدیور.

Even for custom parts, like flanged lead screw nuts for a 3D printer, the ability to read and interpret these drawings is absolutely necessary. These nuts are a bit specialized, and getting their dimensions right means the printer will move accurately. If you're having a hard time reading the drawing, it can really hold up your project. It’s a good example of how these technical details, you know, directly impact the success of a personal project or a larger product design.

How Do We Make Things? - From Design to Production with دکتر لاله کدیور

Once a design is finalized on paper, or more commonly, in a computer-aided design (CAD) program, the next step is to actually make the physical part. This is where processes like CNC machining come into play. CNC stands for Computer Numerical Control, and it’s a way of using computers to control machine tools, like drills and lathes, to create parts with very high precision. If you’re new to mechanical engineering, getting your designs ready for a CNC service means understanding exactly what information they need from your drawings.

For example, when you have a part drawn up in a software like Inventor, that digital model needs to translate perfectly into instructions for the CNC machine. The annotations we discussed earlier, like hole diameters and "thru all" instructions, become direct commands for the machine. It’s like giving a recipe to a chef; every ingredient and step needs to be clear. This process, you know, bridges the gap between the idea in your head and the physical object you can hold, which is a pretty amazing transformation.

Similarly, for custom 3D printer parts, you’re often modeling them yourself and then either printing them or sending them out to a service. The accuracy of your digital model, based on how well you read and apply dimensions from existing parts or create new ones, directly affects how well your 3D printer will function. It’s a very practical application of understanding these drawings. So, for someone like دکتر لاله کدیور, being able to move from a drawing to a manufactured part is a pretty essential skill set.

The practice examples that someone might work through, like interpreting the depth of a part from a diagram, are all about building this bridge between design and manufacturing. It’s not just about drawing lines; it’s about envisioning how that part will be made and how it will interact with other parts. This understanding helps prevent costly mistakes and ensures that the final product meets its design goals, which is, you know, incredibly important in any production setting.

Why Is Precision So Important? - The Role of Tolerancing for دکتر لاله کدیور

In the world of making things, simply stating a dimension isn't always enough. You also need to think about how much variation is acceptable for that dimension, because no manufacturing process can make a part absolutely perfect every single time. This is where the idea of tolerancing comes in. Tolerancing sets the allowable limits for how much a part's actual size can differ from its specified size. It’s about ensuring that parts fit together and function correctly, even with slight variations that happen during production.

For instance, when you're dealing with a fitting, you might see specifications about using the "minimum circumscribed" or "maximum inscribed" circle to tolerance a diameter. This sounds a bit technical, but it’s basically saying that for a hole, the actual diameter can't be smaller than a certain size (minimum inscribed), and for a shaft, its diameter can't be larger than a certain size (maximum circumscribed). This ensures that a shaft will always fit into a hole, or that a part will fit within a specific space, which is, you know, pretty crucial for assembly.

The phrase "thru all" also plays a part in precision. While it tells you the hole goes all the way through, it also removes a potential source of error by clarifying the depth. Without it, someone might assume a partial depth, leading to a part

- Ome Thunder

- Riley Green Political Party

- Froot Vtuber Cheating

- Christopher Walken Net Worth

- Is Cal Raleigh Married

Diameter Symbol (ø, Ø) - Copy and Paste Text Symbols - Symbolsdb.com

Diameter Ø Symbol Mathematical Notation Circle, PNG, 2000x2179px

Diameter symbol Ø - Autodesk Community