ایران خودرو دیزل - Precision In Every Part

Have you ever stopped to think about what goes into making something as substantial as a large vehicle? It's more than just putting pieces together; it's about incredible precision, a deep grasp of how things fit, and a keen eye for every little detail. For companies like ایران خودرو دیزل, building trucks or buses means ensuring every component, down to the tiniest measurement, is exactly right. This focus on exactness is what makes a vehicle dependable and safe for the road, you know?

The journey from an initial concept to a finished vehicle is truly quite a process. It involves a lot of smart people working together, from designers sketching out ideas to engineers figuring out how to make those ideas real, and then the folks on the factory floor putting it all together. Every step of the way, there's a constant need for clarity and accuracy. It's like building with very specific building blocks, where each one has to be the correct shape and size for the whole structure to stand tall and work well, as a matter of fact.

When we talk about things like engine parts, chassis components, or even the small bits that make up the electrical system, the drawings and specifications are the language that everyone speaks. These technical papers are filled with symbols and numbers that tell a very important story about how a part should look and fit. Getting these details right is absolutely essential for making a vehicle that performs as expected, and honestly, it's what separates a good product from one that just doesn't quite measure up.

- Daisys Destruction

- Ome Thunder

- Desmond Doss The Unyielding Spirit Of A Conscientious Objector

- Sotwe T%C3%BCrkk

- Richard Hoffman Police

Table of Contents

- What Do Symbols on Technical Drawings Really Tell Us?

- Understanding Diameters in ایران خودرو دیزل's World

- How Do We Make Sense of Assembly Instructions?

- Decoding Annotations for ایران خودرو دیزل Components

- Why Is Precision So Important in Manufacturing?

- Ensuring Quality for ایران خودرو دیزل Vehicles

- What Happens When Parts Don't Quite Fit?

- The Role of Tolerances for ایران خودرو دیزل

What Do Symbols on Technical Drawings Really Tell Us?

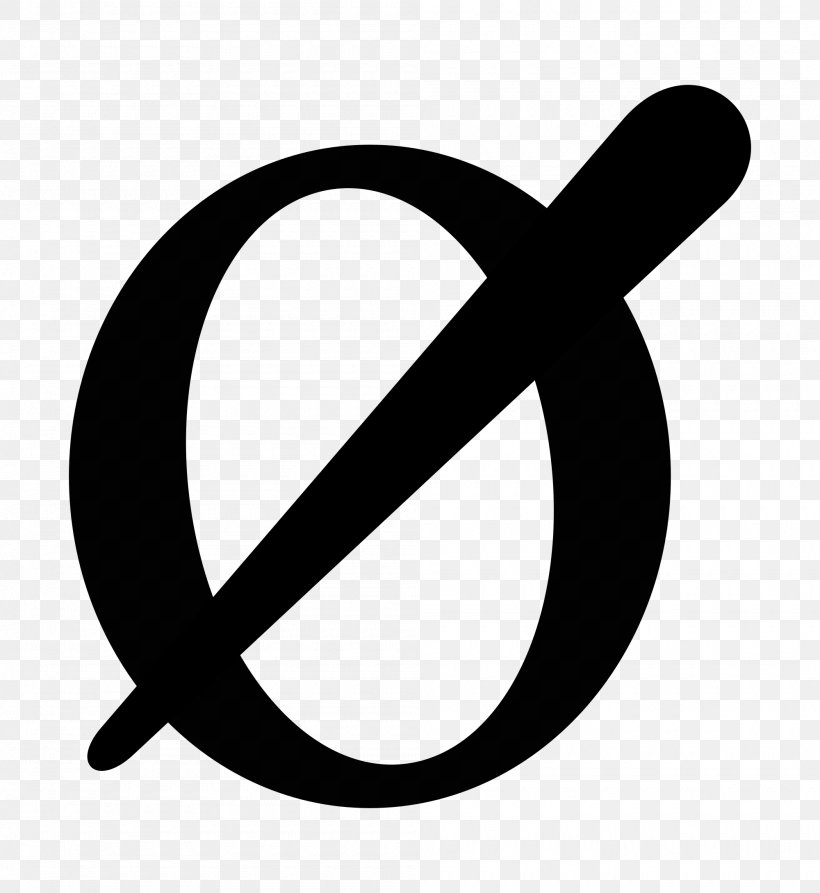

Technical drawings are like a secret language for those who build things. They are packed with symbols and numbers, each one carrying a specific instruction or piece of information. For example, when you see a symbol that looks like a circle with a line through it, that's generally a sign for a diameter. It tells you the size of a round feature, like a hole or a shaft. This kind of mark is absolutely key for anyone trying to make a part or put different parts together, so it's very important to get it right. It's pretty much the alphabet of manufacturing, you know?

Think about a little part like a stepper motor, which might be used in some smaller systems within a larger vehicle. A drawing for such a motor might list the pitch diameter of a gear, or pinion, connected to it as "ø6." This means the gear is six millimeters across its specific measurement point. Or, consider a tiny resistor, a common electrical piece; its drawing might show "φ0.55mm" for the lead, which is the little wire sticking out. These symbols, ø and φ, are similar, and they both point to a circular measurement, pretty much always. They're telling you the exact roundness and size, which is quite useful.

Sometimes, a drawing will give you even more clues, like saying a wire is "24 swg." This is another way to describe its thickness, a standard measurement that translates to a specific diameter, like 0.559 millimeters. So, when a drawing says "φ0.55mm" and also "24 swg," it's reinforcing the same idea, giving you a very clear picture of the wire's physical size. This kind of double-checking in the drawing helps make sure there's no confusion, which is, honestly, a good thing when you are building something complex.

- Buffstream

- Bonnie Blue 1000 People Video

- Aisah Sofey Leaked

- %D9%83%D9%85 %D8%A7%D9%84%D9%85%D8%B3%D8%A7%D9%81%D8%A9 %D8%A8%D9%8A%D9%86 %D8%A7%D9%8A%D8%B1%D8%A7%D9%86 %D9%88%D8%A7%D8%B3%D8%B1%D8%A7%D8%A6%D9%8A%D9%84

- Squirrel Girl Summer Skin Glitch

Understanding Diameters in ایران خودرو دیزل's World

In the world of making vehicles, like those from ایران خودرو دیزل, every single component has to fit together just so. This means that understanding diameters is not just a nice-to-have skill; it's absolutely necessary. Whether it's a hole for a bolt, a shaft for a spinning part, or even the tiny wires that carry electrical signals, their roundness and size are described using these diameter symbols. If a hole is a tiny bit too small, a bolt won't go in. If it's a tiny bit too big, the connection will be loose, and that's not something you want in a vehicle that needs to be dependable, is that right?

When a drawing specifies "Ø 5," it's telling the person doing the work that a hole needs to be drilled to a five-millimeter size. This instruction is very direct and leaves little room for guesswork. Sometimes, you'll see "thru all" added to this, which means that the hole goes all the way through the material, rather than just partway. These simple additions make a big difference in the workshop, making sure the part is made correctly the first time. It's all about being extremely clear, so there's no room for mistakes, which saves time and materials, too it's almost a given.

The symbols for diameter, like the circle with a slash (⌀) or the lowercase letter ø, are pretty much universal in engineering drawings. While they might look a little different depending on the typeface used, their meaning stays the same. This consistency helps people from different places and different backgrounds read the same drawing and understand it in the same way. For a company like ایران خودرو دیزل that might work with suppliers or partners from various places, this common language of symbols is extremely valuable, you know, for smooth operations.

How Do We Make Sense of Assembly Instructions?

Beyond individual part dimensions, technical drawings also give us clues about how parts come together. Sometimes, a drawing will have a note like "4 x" next to a feature. This isn't just a random mark; it means that the particular feature, whatever it is, appears four times on the drawing in a similar way. So, if there's a specific hole or a certain type of corner, and it says "4 x," you know to look for four identical instances of it. This saves space on the drawing and makes it quicker to read, as a matter of fact.

Then there are more complex shapes. Imagine a plastic piece that needs to have an oval hole. A drawing might show something like "ø12 x25l." The "ø12" part tells us the width of the oval, which is twelve millimeters across its circular dimension. The "x25l" is giving us the length of the oval, so it's twenty-five millimeters long. This combination of numbers helps describe a non-circular shape with precision, which is pretty useful for parts that aren't just simple circles or squares. It's a way to capture the full form, literally.

When you're looking at an AutoCAD drawing, which is a common type of digital blueprint, you might see annotations like "R1.25 typ" or "2xø1.0." "R1.25 typ" means a radius of 1.25 millimeters, and "typ" indicates it's a "typical" feature, meaning it's likely found in similar places on the part without being explicitly marked everywhere. "2xø1.0" means there are two holes, each one millimeter in diameter. These kinds of notes are absolutely essential for understanding how a part is meant to be made and how it fits into a bigger picture, so they are quite important.

Decoding Annotations for ایران خودرو دیزل Components

For a company like ایران خودرو دیزل, which manufactures a variety of vehicle components, reading and understanding these drawing annotations is a daily task for many people. It's how they ensure that every single part, whether it's a large metal frame piece or a small bracket, comes out of the production line exactly as the engineers intended. These annotations are the instructions that guide the machines and the people making the parts, pretty much telling them what to do. Without clear annotations, there would be a lot of guesswork, which is something you want to avoid.

Consider a part that needs to be machined by a CNC service. These services use computer-controlled machines to cut and shape materials with incredible accuracy. To do their job, they rely entirely on the precise measurements and annotations on the drawings. If a drawing says "ø1.25" for a hole at the bottom of a part, the CNC machine will cut a hole of exactly that size in that spot. Any misinterpretation could lead to a part that doesn't fit, causing delays and wasted materials, which is not good for anyone, you know.

Sometimes, a drawing might show a cross-section of a part, and you need to figure out its depth. This can be a bit tricky for someone new to mechanical engineering. You might see a diagram and wonder how to interpret the depth of a specific section. This is where understanding how different views on a drawing relate to each other becomes really important. It's like looking at a map and trying to figure out the height of a mountain from contour lines; you need to understand the conventions. For ایران خودرو دیزل, getting the depth right means that parts like engine blocks or transmission casings have the correct internal spaces for other components to fit, which is quite vital.

Why Is Precision So Important in Manufacturing?

When you're making something as intricate and functional as a vehicle, precision isn't just a fancy word; it's the bedrock of quality and safety. Every single part, from the largest chassis member to the smallest screw, has to be made within very specific limits. If parts are even slightly off, they might not fit together properly, or they might wear out faster than they should, or worse, they could fail in a way that puts people at risk. This is why engineers spend so much time making sure every dimension is exactly right, as a matter of fact.

Think about building something like a custom 3D printer. You might find specific components, like flanged lead screw nuts, that you plan to use. But then you run into trouble reading the dimensions on their datasheet. Maybe you're not sure what a certain symbol means, or how one measurement relates to another. This difficulty highlights why clear, universally understood technical drawings are so important in the manufacturing world. If you can't read the drawing, you can't make the part, or you'll make it wrong, which is pretty much a guarantee.

The consequences of a lack of precision can be far-reaching. A small error in one part can cause a chain reaction, leading to problems in assembly, performance issues, or even structural weaknesses in the final product. This is why companies that build vehicles invest so much in quality control and in making sure their manufacturing processes are extremely accurate. They know that every millimeter, every degree of angle, matters a great deal, and honestly, it shows in the final product's performance and reliability.

Ensuring Quality for ایران خودرو دیزل Vehicles

For a large-scale producer like ایران خودرو دیزل, the commitment to precision directly translates into the quality of their vehicles. Every truck or bus that leaves their facilities is a collection of thousands of parts, all designed to work together in harmony. This harmony is only possible if each part meets its exact specifications. It means that the engineering drawings aren't just suggestions; they are strict rules that must be followed during production, pretty much without exception.

When parts are sent to external manufacturing services, like CNC shops, the clarity of the drawings becomes even more critical. These services rely entirely on the information provided to them to produce components. If the drawings are ambiguous or hard to read, there's a higher chance of errors. That's why having drawings that are clear, consistent, and use standard symbols is absolutely key for smooth operations and for getting the right parts back, you know, every single time.

The attention to fine detail, from the pitch diameter of a pinion to the specific lead diameter of a resistor, is what builds trust in a product. It's the silent promise that the vehicle you're driving or riding in has been put together with the utmost care and accuracy. This focus on getting every measurement right is a core part of how companies like ایران خودرو دیزل ensure their vehicles are not just functional, but also safe and dependable for years to come, which is something customers really appreciate, as a matter of fact.

What Happens When Parts Don't Quite Fit?

Imagine trying to put together a puzzle where some pieces are slightly too big or too small. It just doesn't work, does it? The same goes for manufacturing. When parts don't quite fit, it can lead to a whole host of problems on the assembly line and beyond. It can slow down production, require costly rework, and in the worst cases, lead to product failures. This is why the concept of "tolerance" is so important in engineering and manufacturing, honestly.

Tolerance refers to the acceptable amount of variation a part can have from its specified dimension. No manufacturing process is absolutely perfect; there will always be tiny differences. So, engineers define a small window, or range, within which a part is still considered acceptable. For example, a hole might be specified as "5mm +/- 0.02mm," meaning it can be anywhere from 4.98mm to 5.02mm and still be good. This small allowance helps production, but it also means the parts will still fit and work correctly, which is quite clever.

Sometimes, the way a diameter is toleranced can be quite specific. You might come across a situation where it's about using the "minimum circumscribed" or "maximum inscribed" circle to check the diameter. This is a more advanced way of making sure a round part, even if it's not perfectly round, will still fit correctly with other parts. It's about ensuring functionality even with slight real-world imperfections. Getting these tolerance definitions right is very important for making sure parts are interchangeable and that assembly goes smoothly, you know.

The Role of Tolerances for ایران خودرو دیزل

For a company like ایران خودرو دیزل, managing tolerances is a fundamental part of their production process. It's how they ensure that every engine component, every chassis part, and every piece of the suspension system fits together properly, time after time. Without carefully defined and controlled tolerances, the consistency and reliability of their vehicles would be impossible to maintain. It's pretty much a constant balancing act between being precise enough and allowing for practical manufacturing variations.

When a drawing specifies "thru all" for a hole, it's not just about the depth; it's also about the tolerance for that depth. It removes the requirement for a specific depth measurement, implying that as long as the hole goes all the way through, it meets the design intent. This kind of instruction simplifies things for the person making the part while still ensuring the functional requirement is met. It's a smart way to communicate design intent clearly, you know, without overcomplicating things.

The careful attention to every detail, from the symbols on a drawing to the specific tolerances allowed for each part, is what truly defines the quality of a manufactured product. For ایران خودرو دیزل, this means that the vehicles they produce are built to last, perform well, and meet the high expectations of their users. It's a testament to the hard work and precision that goes into every single component, making sure that when you see one of their vehicles, you know it's been made with great care, as a matter of fact.

This article has explored the crucial role of precise technical drawings and the importance of understanding their symbols and annotations in manufacturing, using examples like diameter measurements, assembly instructions, and the concept of tolerances. We've seen how these fundamental engineering principles are absolutely vital for producing high-quality, dependable vehicles, much like those created by ایران خودرو دیزل. The ability to interpret these technical details accurately is what ensures that every component fits just right, contributing to the overall strength and reliability of the final product.

- Aishah Sofey Leak Free

- Yeti Dogs Anchorage

- Denzel Washington Training Day

- The Enigmatic Journey Of Theo James A Star In The Making

- Slang Eiffel Tower

Diameter Symbol (ø, Ø) - Copy and Paste Text Symbols - Symbolsdb.com

Diameter Ø Symbol Mathematical Notation Circle, PNG, 2000x2179px

Diameter symbol Ø - Autodesk Community