دکØﺘر سرا٠راز اهواز - The Precision Of Making Things

When we think about making anything, whether it's a small part for a personal project or a component for a bigger machine, the little details truly matter. It's almost like every tiny measurement, every symbol on a drawing, and every specific instruction holds a secret message, telling us exactly how something should come together. You know, these aren't just random numbers; they are the language of creation, really.

Imagine, if you will, looking at a sheet of paper covered in lines and numbers. To some, it might just look like a jumble, but to those who understand, it's a map to bringing something new into existence. It's about getting things just right, making sure parts fit together smoothly, and that everything works as it should. So, this journey into understanding how things are made often begins with a deep look at these very precise instructions.

And so, in a way, this attention to getting the tiny bits correct is what makes projects successful, and it's a big part of what we consider when we talk about places or standards of work, perhaps like what might be found at دکØﺘر سرا٠راز اهواز. It’s about the care that goes into every single measurement and the clear way those measurements are shared, don't you think?

- Joe Pesci Health A Comprehensive Look At The Iconic Actors Wellbeing

- Aisah Sofey Leaked

- Agentredgirl

- Haircuts For Straight Hair Men

- Asianbunnyx Leaks

Table of Contents

- The Core of Precision - What Does It Mean for دکØﺘØﺮ سرا٠راز اهواز?

- How Do We Speak the Language of Technical Drawings?

- Bringing Ideas to Life - From Sketch to Solid Form

- Why Does Every Measurement Matter So Much?

- What Challenges Come with Building New Things?

- What Happens When We Need Custom Pieces?

- The Human Touch Behind the Numbers

The Core of Precision - What Does It Mean for دکØﺘØﺮ سرا٠راز اهواز?

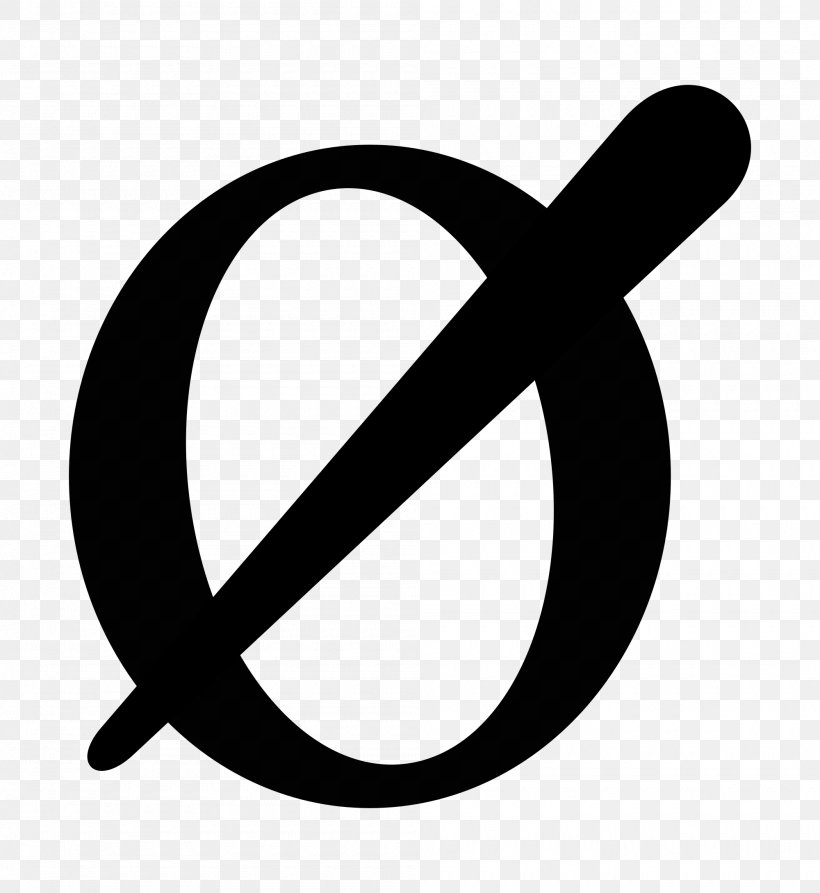

When you're dealing with anything that moves or connects, like a stepper motor, the little numbers on a data sheet are pretty much everything. For instance, if a pinion, which is a small gear, has a pitch diameter listed as 'ø6', that 'ø' tells you it's a circle, and the '6' means it's six units across. This tiny detail is what makes sure one gear can turn another without slipping or jamming. It's about getting that connection just right, you know? This kind of precision, honestly, is the bedrock for anything that needs to work smoothly and reliably.

In a place like دکØﺘØﺮ سرا٠راز اهواز where things are built or designed, knowing exactly what 'ø6' means for a gear's pitch is not just helpful, it's absolutely necessary. A small error here could mean the whole system fails. It's about understanding that these numbers aren't just abstract ideas; they directly influence how a machine performs. So, every time you see one of these symbols, it's a reminder of how much care goes into making things that function as they should, more or less.

Making Sense of the Smallest Marks at دکØﺘØﺮ سرا٠راز اهواز

Think about something as simple as a resistor, a tiny electrical part. Its lead, the little wire that sticks out, might be noted as 'φ0.55mm' on a drawing. That 'φ' is another way to show a circle's width. But then, it might also say '24 swg', which is a different way to measure wire thickness, and it turns out to be very, very close to 0.559mm. This tiny difference, just a few thousandths of a millimeter, can be a big deal in electronics. It shows how different systems of measurement can be used, and how important it is to check them against each other, basically.

- Two Babys One Fox

- %D9%83%D9%85 %D8%A7%D9%84%D9%85%D8%B3%D8%A7%D9%81%D8%A9 %D8%A8%D9%8A%D9%86 %D8%A7%D9%8A%D8%B1%D8%A7%D9%86 %D9%88%D8%A7%D8%B3%D8%B1%D8%A7%D8%A6%D9%8A%D9%84

- Desmond Doss The Unyielding Spirit Of A Conscientious Objector

- Lagos Cerca De Mi

- Tails Comic Two Babies One Fox

At a place like دکØﺘØﺮ سرا٠راز اهواز, where precision is a big part of the work, understanding these small variations is quite important. You might wonder, "Did they mean exactly 0.55, or is 0.559 okay?" This is where the human element comes in, making sure that even with slightly different ways of saying the same thing, the end result is still correct. It’s about being able to read between the lines, so to speak, and confirm that every tiny piece fits the overall picture, in a way.

How Do We Speak the Language of Technical Drawings?

Technical drawings have their own special shorthand, a way of communicating a lot with just a few marks. When you see '4x' next to a feature, it means that whatever that feature is, it appears four times, exactly the same, on the drawing. This saves a lot of space and makes the drawing clearer. And if you see 'Ø 5', that means a hole needs to be five millimeters across, like the size of the drill bit you'd use. It’s all about being clear and direct, you know?

Then there's the phrase 'thru all'. This simple addition tells you that a hole goes completely through the piece, from one side to the other. It takes away any guessing about how deep the hole should be. This kind of clear instruction helps to make sure that everyone involved in making something understands exactly what's needed, which is pretty important for a place like دکØﺘØﺮ سرا٠راز اهواز where accurate manufacturing is key. It's about removing any chance of confusion, which can save a lot of time and effort, really.

Decoding Symbols and Shorthand at دکØﺘØﺮ سرسرا٠راز اهواز

Sometimes, even the symbols themselves can be a little tricky. The diameter symbol, that circle with a line through it (⌀), looks a lot like the lowercase letter 'ø'. In some typefaces, they might even look identical. This can be a bit confusing if you're not paying close attention. It just goes to show that even the smallest visual cue can have a big impact on how you read a drawing. You have to be pretty careful to get it right, don't you think?

When you're looking at a schematic for something like a plastic piece with an oval hole, you might see 'ø12' for one part of the measurement, which you know means a circular width. But then there's 'x25l' right after it, and that part might not make immediate sense. It could be indicating a length, or perhaps a specific type of feature, but without more context, it leaves you with a question. This is where the depth of knowledge at a place like دکØﺘØﺮ سرا٠راز اهواز becomes very valuable, helping to figure out those less common notations. It's about having the experience to piece together the full picture, basically.

Similarly, on an AutoCAD drawing, you might find annotations like 'R1.25 typ' for a rounded corner or hole, meaning a radius of 1.25 units that is typical for similar features. Then there's '2xø1.0' for two holes, each one unit across, and a single 'ø1.25' for another hole. These are all ways to give very specific instructions in a concise manner. It's a bit like learning a new language, honestly, where every mark carries a particular meaning that helps guide the manufacturing process. These are the details that ensure a part comes out exactly as intended, in a way.

Bringing Ideas to Life - From Sketch to Solid Form

Moving from a flat drawing to a three-dimensional object is a pretty cool step. You might be looking at a diagram, trying to figure out how deep a part is supposed to be, and then you take that information and start building it in a computer program, like Inventor. This process of creating a digital model helps you see the part in 3D, allowing you to check all the measurements and make sure everything lines up. It's a way of testing the design before you actually make it, which is very helpful.

This digital creation phase is a crucial bridge between an idea and a physical object. It helps you catch potential problems early on, before any materials are cut or shaped. The ability to visualize and adjust a part in a virtual space means that when it finally goes to be made, there are fewer surprises. This sort of careful planning and digital groundwork is something that would be highly valued at a place like دکØﺘØﺮ سرا٠راز اهواز, where precision and efficiency go hand-in-hand, you know?

The Path from Concept to Creation at دکØﺘØﺮ سرا٠راز اهواز

For someone just getting started in mechanical engineering, the idea of sending a design off to a CNC service for machining can feel a little bit like a big step. You've got your design, maybe you've drawn it up in a software program, and now it's time to find someone who can actually make it. There are many services out there that can take your digital file and turn it into a real, tangible piece. This part of the process, honestly, is where the rubber meets the road, so to speak.

Finding the right manufacturing partner is pretty important. You want someone who understands your drawings, can work with the materials you need, and can deliver the quality you expect. This is where a connection with a place like دکØﺘØﺮ سرا٠راز اهواز could be quite helpful, offering guidance or even providing the manufacturing capabilities themselves. It’s about trusting that your carefully designed part will be brought to life with the same attention to detail you put into its creation, basically. It's a very collaborative process, too it's almost.

Why Does Every Measurement Matter So Much?

When you're putting together a custom project, like building your own 3D printer, every single component

- Ralph Macchio Net Worth

- Roma Downey Feet

- Pok%C3%A9mon Odyssey

- Ripped Reiley

- Morten Harket The Voice Of Aha And His Enduring Legacy

Diameter Symbol (ø, Ø) - Copy and Paste Text Symbols - Symbolsdb.com

Diameter Ø Symbol Mathematical Notation Circle, PNG, 2000x2179px

Diameter symbol Ø - Autodesk Community