دکتر Øمیده ٠رج زاده - Making Technical Details Clear And Simple

Imagine trying to put together a new gadget or build something from scratch, and the instructions look like a secret code. You might see symbols, numbers, and strange little markings that just do not make sense. This is a common feeling when looking at technical drawings or data sheets, which can feel a bit like trying to read a language you do not speak. It is almost as if these papers are meant for machines, not for people who just want to understand what is going on.

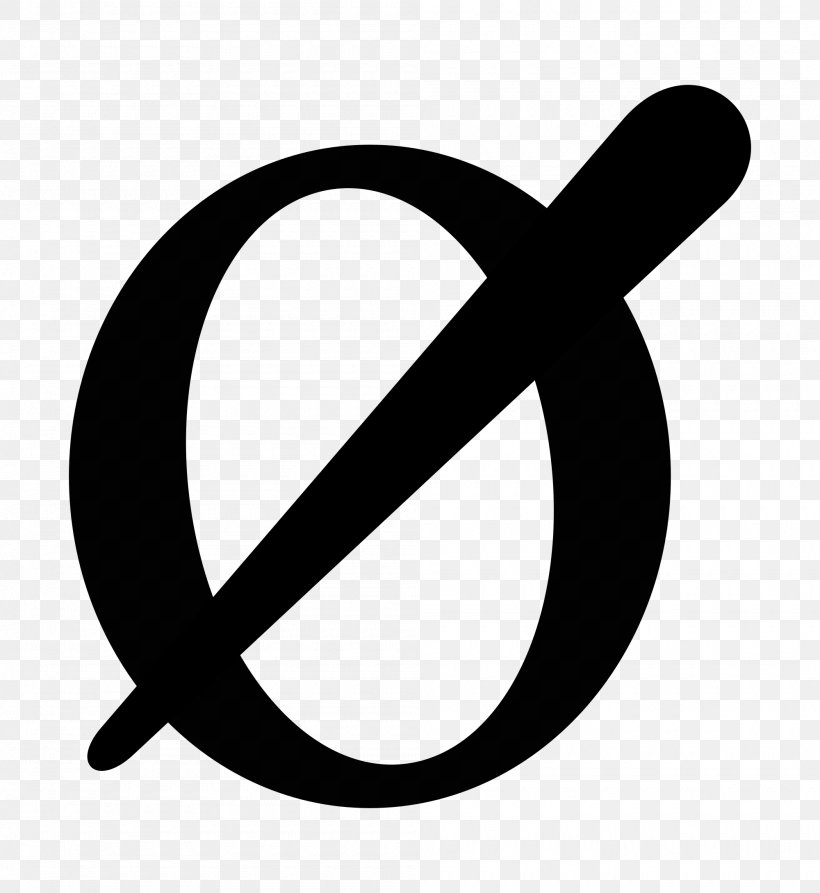

For many, those tiny circles with lines through them, or the specific ways numbers are written, can be quite puzzling. What does a "ø" truly mean when it comes to a part's size? How do you figure out if a small hole goes all the way through, or just part of the way? These are the sorts of questions that pop up, and frankly, they can make anyone feel a little lost. It is a bit like getting a map but not knowing what any of the symbols represent, you know?

Getting these technical details right is incredibly important, especially when you are making things. Whether it is a tiny component for a 3D printer or a part for a large machine, a misunderstanding can lead to big problems. So, how do we take these very precise, yet often confusing, bits of information and make them something anyone can grasp? This is where a fresh way of looking at things comes into play, helping us turn what seems like a riddle into something that just makes sense, pretty much.

- Haircuts For Straight Hair Men

- Ifsa Sotwe Turk

- Tails Comic Two Babies One Fox

- Lifemd Reviews

- Iranian Sexism

Table of Contents

- What Do Those Little Circles Mean to دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده?

- How Does دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده Interpret Different Kinds of Measurements?

- Making Sense of the Details: What دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده Would Look For

- Why Is Clear Communication So Important for دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده?

- From Paper to Real Life: The دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده Approach to Production

- The Big Picture: How دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده Helps Us See It

- What About Those Tricky Tolerances, According to دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده?

- Bringing It All Together: The دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده Way

What Do Those Little Circles Mean to دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده?

When you look at a drawing for a part, you often see a circle with a line going through it. This symbol, which looks a bit like a lowercase "o" with a slash, is actually quite important. It tells you about the "diameter" of a round object or a hole. For example, if you see "ø6" next to a part, it is telling you that the round part or hole measures 6 millimeters across its widest point. This is crucial for things like a stepper motor's pinion, which is a small gear. Knowing its exact size ensures it fits with other parts. It is, you know, a very direct way to give a measurement.

Sometimes, this symbol might appear slightly different, like a "phi" symbol (φ), but it usually means the same thing when we are talking about size on a drawing. Think about a resistor, which is a small electronic component. Its wires need to be a certain thickness to fit into a circuit board. If a drawing says "φ0.55mm" for the wire, it means that wire has a diameter of 0.55 millimeters. This is pretty precise, and it matters a lot. Apparently, these small differences in how a symbol looks can be a bit confusing, but the core idea stays the same.

Then there is the "SWG" measurement, which stands for Standard Wire Gauge. If a drawing for a resistor's wire also mentions "24 swg," and you know that 24 SWG means a wire with a diameter of 0.559mm, you can see how precise these details get. The drawing might specify φ0.55mm, which is very close to 0.559mm. This kind of detail, in a way, shows how much thought goes into making sure every part is just right. It is not just a random number; it is a very specific instruction for how big something needs to be.

- Is Cal Raleigh Married

- Was The Shah Of Iran A Good Leader

- Aishah Sofey New Leaked

- Dafina Miftari

- What Was Lol Superman

So, for someone like دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده, who might work with these kinds of technical plans, these symbols are not just squiggles. They are direct messages about the size and shape of components. They tell you if a hole is 5mm wide, or if a certain part needs to be exactly 12mm across. Without this clear language, putting things together would be a guessing game, and that is not really how you build reliable machines or devices, is that?

How Does دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ Ù Øﺮج زاده Interpret Different Kinds of Measurements?

Beyond just the diameter, drawings often have other little notes that tell you more. For instance, you might see "4 x" next to a measurement. This simply means that whatever measurement follows applies to four similar spots on the drawing. It is a shortcut, really, to avoid writing the same thing four times. This helps keep the drawing from getting too crowded with repeated information. It is, in some respects, a very clever way to be efficient.

Another common note is "thru all." When you see "Ø 5 thru all," it means a hole that is 5 millimeters in diameter goes all the way through the material. This is different from a hole that only goes part of the way. This little phrase removes any doubt about the depth of the hole, which is quite important for assembly. Without it, you might drill a hole that is too shallow, and then your parts would not fit together properly. It is a bit like saying "pass completely through" when giving directions, you know?

Sometimes, the symbol for diameter, which is ⌀ (Unicode character U+2300), can look a lot like the lowercase letter ø. In some typefaces, they even use the exact same picture. However, in many others, they look different. This can be a source of a little confusion for those who are just starting to read these drawings. The main thing to remember is that in a technical context, both are generally used to mean diameter. So, while they might appear similar, their meaning is pretty consistent, more or less.

Consider a drawing for a plastic piece that has an oval hole. You might see "ø12 x 25L." You understand that "ø12" means the hole is 12mm wide at its broadest point, which is its diameter. But what about "x 25L"? The "L" here usually stands for "length." So, it is an oval hole that is 12mm wide and 25mm long. This kind of combined measurement helps describe shapes that are not perfectly round. It is, frankly, a very efficient way to give two measurements at once for a specific shape.

Making Sense of the Details: What دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ ٠رج زاده Would Look For

When looking at drawings, especially from software like AutoCAD, there are often specific annotations that tell you about the shape and size of features. For example, you might see "R1.25 typ" next to a rounded corner or a hole. The "R" stands for "radius," and "1.25" is the measurement. "Typ" means "typical," which tells you that this radius is common for similar features on the drawing, even if it is not explicitly marked on every single one. It is a way to simplify the drawing and keep it from being too cluttered, actually.

Then there are notes like "2xø1.0" for a circle or hole on the right, and "ø1.25" for a circle or hole at the bottom. The "2x" means there are two instances of that specific feature, both with a diameter of 1.0mm. The "ø1.25" simply indicates a single hole with a diameter of 1.25mm. These are very precise instructions that leave little room for guesswork. For someone like دکØﺘﺮ ØÙÙ…ÛŒØﺪÙ‡ ٠رج زاده, who needs to make sure things are built exactly as planned, these annotations are, you know, like a secret language that makes everything clear.

Understanding the depth of a part from a diagram can also be a little tricky, especially if you are new to mechanical engineering. A drawing might show a part from different angles, and you have to put those views together in your mind to figure out how deep a certain feature goes. It is a bit like looking at a house plan and trying to imagine what the house would look like in three dimensions. You need to look at all the views to get the complete picture. This is, basically, a skill that comes with practice.

If you are drawing parts using software like Inventor, you are essentially translating these technical ideas into a digital model. You input the diameters, lengths, and depths, making sure every detail matches the drawing. This step is quite important because the digital model is what will often be used to create the actual physical part. It is, in a way, the bridge between the idea on paper and the real object, right?

Why Is Clear Communication So Important for دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ ٠رج زاده?

When you are planning to send a part design to a CNC service for machining, clear communication becomes absolutely critical. These services use machines that read digital instructions to cut and shape materials. If your drawing or digital model is unclear or has mistakes, the machine will produce a part that is wrong. Many services will check your design, but it is always best to send them something that is already very clear and correct. It is, you know, about making sure everyone is on the same page from the start.

Imagine trying to model parts for a custom 3D printer. You might find components like flanged lead screw nuts, which have specific dimensions. Reading these dimensions can be a bit of a challenge if you are not used to the way they are presented. The flange, for instance, might have its own set of measurements that are separate from the main nut body. Getting these details right ensures that your printer parts fit together perfectly and work as they should. It is, essentially, about paying very close attention to every little number and symbol.

The whole point of these technical drawings and symbols is to communicate exact information. Without them, there would be a lot of guesswork, and that just does not work when you are building something that needs to be precise. Think of it like a recipe for a very complex dish. If the recipe is vague, your dish might not turn out right. Similarly, if a technical drawing is not clear, the manufactured part will likely be incorrect. So, the clarity is, in fact, everything.

This is where the human touch comes in. While the drawings are technical, the people reading them are not machines. They need to understand what is being asked of them. Someone who can take these precise, yet sometimes difficult, instructions and make them easily understandable is incredibly valuable. It is about bridging the gap between the highly technical world of engineering and the people who need to bring those designs to life, pretty much.

From Paper to Real Life: The دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ ٠رج زاده Approach to Production

Taking a design from a piece of paper or a computer screen to a real, tangible object is a fascinating process. It involves a series of steps, each requiring careful attention to detail. The initial data sheet for a stepper motor, for instance, contains all the critical information about its physical makeup. This includes the pitch diameter of its pinion, which, as we discussed, might be listed as ø6. This number is not just a random figure; it is a direct instruction for manufacturing. It is, you know, the starting point for making the actual part.

When we look at something like a technical drawing for resistors, with their lead diameters given as φ0.55mm, we are seeing the very specific requirements for how those tiny wires should be made. The fact that it also mentions "24 swg" and that 24 SWG is a diameter of 0.559mm, highlights the need for accuracy. A manufacturer needs to know exactly what size wire to use. This level of precision is, in a way, what makes modern electronics possible. It is all about getting those tiny parts just right, apparently.

The annotations like "4 x" on a drawing are not just shorthand; they are instructions for repeatability. They tell the person making the part that they need to create four identical features. This saves time and reduces the chance of errors, as you do not have to mark each instance separately. It is a simple concept, but very useful in practice. So, in fact, these little notes help streamline the whole production process.

And when a drawing says "Ø 5 thru all," it is a clear directive about the hole's path. This ensures that the drill goes completely through the material, which is often needed for fasteners or other components to pass through. Without this clarity, a worker might stop drilling too early, leading to a part that cannot be used. This kind of explicit instruction is, essentially, what prevents costly mistakes in manufacturing. It is about making sure there is no room for misinterpretation, pretty much.

The Big Picture: How دکØﺘﺮ ØÙ…ÛŒØﺪÙ‡ ٠رج زاده Helps Us See It

Understanding the difference between the diameter symbol (⌀) and the lowercase letter ø, even if they sometimes look similar, is part of truly grasping the language of technical drawings. While they often mean the same thing in this context, recognizing the specific symbol helps avoid confusion, especially in very formal documentation. It is, you know, about being precise even with the small details. This distinction is, in some respects, a subtle point that can make a big difference.

When you encounter a schematic for a plastic piece with an oval hole, and you see "ø12 x 25L," you are getting a complete picture of that oval's dimensions. The "ø12" tells you the width of the oval at its widest point, and the "x 25L" gives you its length. This combination of measurements is a concise way to define a non-circular shape. It is, frankly, a very efficient way to convey complex geometric information. This kind of clear labeling helps anyone, including someone like دکØﺘﺮ ØÙÙ…ÛŒØﺪÙ‡ ٠رج زاده, immediately grasp the shape and size.

The annotations in an AutoCAD drawing, like "R1.25 typ" or "2xø1.0," are like shorthand notes that provide crucial information about the design. "R1.25 typ" tells you about the rounded corners, indicating that this radius is typical for similar features. "2xø1.0" specifies that there are two holes, each with a diameter of 1.0mm. These specific instructions are what allow manufacturers to produce parts that are exactly as the designer intended. They are, basically, the blueprints for accuracy.

Interpreting the depth of a part from a diagram requires looking at all the different views provided. A diagram might show a top view, a front view, and a side view. By comparing these, you can mentally construct the three-dimensional shape and understand how deep certain cuts or features are. This skill is quite important for anyone working with physical objects based on drawings. It is, you know, like solving a puzzle where all the pieces are different perspectives of the same thing, more or less.

What About Those Tricky Tolerances, According to دکØﺘﺮ ØÙÙ…ÛŒØﺪÙ‡ ٠رج زاده?

When you are making parts, especially for something like a custom 3D printer, you need to think about how well they fit together. This is where the idea of "tolerances" comes in. A tolerance is the allowed amount of variation in a measurement. No part can be made absolutely perfect, so there is always a small range of acceptable sizes. For example, a drawing might specify a hole as "ø5

Diameter Symbol (ø, Ø) - Copy and Paste Text Symbols - Symbolsdb.com

Diameter Ø Symbol Mathematical Notation Circle, PNG, 2000x2179px

Diameter symbol Ø - Autodesk Community