رینگ اسپرت ۲۰۶ - Making Sense Of Your Project Plans

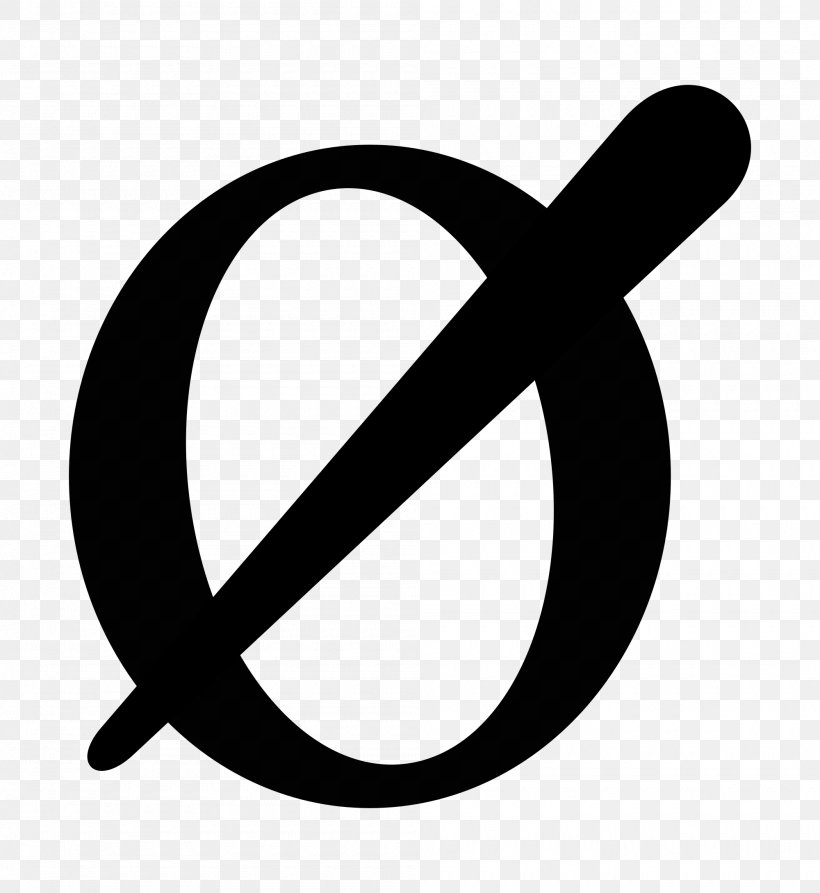

Have you ever found yourself staring at a technical drawing, perhaps for something like a part of your رینگ اسپرت ۲۰۶ project, and felt a little lost? It's a pretty common feeling, you know. Those lines and symbols can seem like a secret code if you're not used to them. We're talking about things like the little circle with a slash through it, or maybe a tiny letter 'R' next to some numbers. Getting these details right is, in some respects, incredibly important for anything you're trying to build or put together, whether it's a new gadget or a repair.

It's interesting, isn't it, how much information can be packed into what seems like just a few marks on a page? For instance, when you see a note about a stepper motor, and it mentions the pitch diameter of a small gear, or pinion, being something like ø6, that tiny symbol carries a lot of weight. It tells you about the exact roundness and size needed for that part to fit just right. Without that precise bit of information, your رینگ اسپرت Û²Û°Û¶ might not work as intended, which is, actually, a big deal.

Understanding these specific marks and measurements is a bit like learning a new language, but one that speaks directly to how things are made. From figuring out what 'thru all' means on a hole specification to making sense of resistor wire sizes, each piece of information is there for a reason. It helps make sure that every component, especially for something as particular as your رینگ اسپرت ۲۰۶, comes together exactly as it should. It can be a little tricky, but it's totally worth the effort.

- Joe Pesci Health A Comprehensive Look At The Iconic Actors Wellbeing

- Imskirby The Dog Incident

- Ifsa Sotwe Turk

- Squirrel Girl Summer Skin Glitch

- Duck Dynasty The Wealth Of Willie Robertson

Table of Contents

- Understanding the Roundness Symbol

- What's the Deal with Wire Sizes and رینگ اسپرت ۲۰۶?

- When Drawings Talk About Multiples for Your رینگ اسپرت ۲۰۶

- How Do We Interpret Hole Details and رینگ اسپرت ۲۰۶ Parts?

- Those Tricky Drawing Annotations and Your رینگ اسپرت ۲۰۶

- Getting the Depth Right for Your رینگ اسپرت ۲۰۶ Components

- Making Parts for Your رینگ اسپرت ۲۰۶ Project with CNC

- Deciphering Screw Nut Dimensions for رینگ اسپرت ۲۰۶

Understanding the Roundness Symbol

So, you're looking at a data sheet for a stepper motor, and it says something about the pitch diameter of a small gear, or pinion, being ø6. This little ø symbol is, actually, a pretty common sight in technical drawings, and it stands for diameter. It's a way to show you the measurement across a circle. When you see ø6, it means that particular circular part should measure 6 units across its widest point. It's quite straightforward once you know what it means, but it can be a bit confusing at first, you know?

You might even find yourself, like some folks do, looking up this symbol on places like Wikipedia. It turns out that the ø symbol, which looks a lot like a lowercase 'o' with a line through it, is quite similar to another symbol, ⌀, which is the actual diameter sign in Unicode. Sometimes, these two even share the same visual appearance depending on the type of font used. This small detail, that, can sometimes lead to a tiny bit of confusion, but generally, they point to the same thing: the span of a circular feature. For any رینگ اسپرت Û²Û°Û¶ component that needs to be perfectly round, getting this measurement correct is very important.

The precision here is, in some respects, everything. If a gear's pitch diameter is off, even by a tiny bit, it might not mesh properly with other gears, leading to all sorts of issues with how your machine moves. So, when you see ø6 on a drawing for a stepper motor part, it's not just a random number; it's a specific instruction for how that piece needs to be formed to ensure everything works smoothly in your رینگ اسپرت Û²Û°Û¶. This is why paying close attention to these symbols is, basically, a must.

- Two Babys One Fox

- Froot Cheating

- Exploring The Race Of Steve Perry A Deep Dive Into His Background And Legacy

- Aishah Sofey Erome

- Morgan Wallen Concert Length

What's the Deal with Wire Sizes and رینگ اسپرت ۲۰۶?

Let's say you're looking at a technical drawing for something like resistors, and it mentions the lead diameter as φ0.55mm. Then, it also tells you the wire is 24 SWG. Now, you might wonder, what's the connection there? You might even think, did they mean the same thing? It turns out that 24 SWG, which stands for Standard Wire Gauge, actually corresponds to a wire diameter of about 0.559mm. So, the drawing is giving you two ways to describe the same physical characteristic, and they are, in fact, very close to each other.

The φ symbol, much like the ø symbol we talked about, also represents diameter, especially in some contexts or regions. It's just another way to show that measurement across a circular shape. The slight difference between 0.55mm and 0.559mm might seem tiny, but for very precise electronic components or parts in a رینگ اسپرت Û²Û°Û¶, those small variations can sometimes matter. It's a good reminder that when you're working with these specifications, it's worth checking if different notations refer to the same thing or if there's a tiny, but important, distinction.

This kind of detail is, basically, why people spend time making sure their drawings are clear. When you're dealing with something that has to fit just so, like wires going into a circuit board or specific components for your رینگ اسپرت Û²Û°Û¶, knowing the exact size is, obviously, crucial. It helps avoid situations where parts don't quite fit, or connections aren't as solid as they should be. So, seeing both φ0.55mm and 24 SWG helps confirm that you're looking at a very specific wire size.

When Drawings Talk About Multiples for Your رینگ اسپرت ۲۰۶

Have you ever seen a drawing with a number followed by an 'x', like '4 x', next to a feature? It's a pretty neat shortcut, actually. What it means is that the particular instruction or measurement applies to four different spots on the drawing that look alike. So, instead of having to write out the same dimension four separate times, the designer can just put '4 x' once, and you know it refers to all those similar instances. It's a way to keep drawings from getting too cluttered, which is, in a way, very helpful.

This notation is, you know, quite common in mechanical drawings. It saves space and makes the drawing easier to read, especially when you have a lot of repetitive features, like a series of holes or identical mounting points. For example, if you're building a frame for your رینگ اسپرت ۲۰۶ and it needs four identical holes in its corners, the drawing might just show one hole with the '4 x' annotation. This tells you to replicate that specific hole four times in the specified locations.

Understanding these kinds of shorthand notes is, apparently, a big part of being able to work with technical plans effectively. It helps you quickly grasp the overall design intent without having to search for every single instance of a feature. So, when you see '4 x' on a drawing for a رینگ اسپرت ۲۰۶ part, you immediately know that whatever follows that 'x' applies to four identical spots. It's a simple concept, but very powerful for clear communication in engineering.

How Do We Interpret Hole Details and رینگ اسپرت ۲۰۶ Parts?

When you see something like 'Ø 5' on a drawing, it's telling you that a hole needs to have a diameter of 5 millimeters. This is, you know, the size of the drill bit you'd typically use to make that hole. But sometimes, you'll see something extra, like 'thru all' added right after it. This phrase is, basically, a very important instruction. It means that the hole should go all the way through the material, from one side to the other, without stopping partway. It takes away any question about the depth of the hole.

This 'thru all' note is, in fact, quite useful because it prevents any guesswork. If it wasn't there, you might wonder if the hole was supposed to be a blind hole, meaning it only goes part of the way into the material. But by adding 'thru all', the designer makes it perfectly clear that the hole should pass completely through the component. This is, you know, especially important for parts that need to be fastened together or allow something to pass through them, like in many رینگ اسپرت ۲۰۶ assemblies.

Getting these hole specifications right is, obviously, critical for the fit and function of any piece you're making. Imagine trying to bolt two parts of your رینگ اسپرت Û²Û°Û¶ together, only to find that the holes don't line up or don't go all the way through. That would be, in a way, pretty frustrating. So, when you see 'Ø 5 thru all', you know exactly what kind of hole to create: a 5mm wide opening that goes completely through the material. It's all about leaving no room for misunderstanding.

Those Tricky Drawing Annotations and Your رینگ اسپرت ۲۰۶

Autocad drawings, or any technical drawings for that matter, often have these little annotations that can seem a bit cryptic at first glance. For example, you might see 'R1.25 typ' next to a circle or hole on the left. The 'R' there stands for radius, which is the measurement from the center of a circle to its edge. So, 'R1.25' means that particular curve or fillet has a radius of 1.25 units. The 'typ' is short for 'typical', and it means that this radius is common for similar features throughout the drawing, so you can expect to see it in other places that look alike, which is, honestly, pretty handy.

Then, perhaps next to a hole on the right, you might find '2xø1.0'. We've already talked about 'ø' meaning diameter, and '2x' meaning there are two of them. So, this tells you there are two holes, each with a diameter of 1.0 unit. And then, at the bottom, you might just see 'ø1.25' for another circle or hole, indicating a single hole with a diameter of 1.25 units. Each of these annotations is, in fact, a very precise instruction for how the part should be shaped, especially for something that needs to be put together carefully, like a component for your رینگ اسپرت Û²Û°Û¶.

These symbols and numbers are, basically, the language of manufacturing. They ensure that when someone else tries to make the part you've drawn, they get it exactly right. From the roundness of a corner to the exact size of a hole, every detail matters. Understanding 'R' for radius, 'ø' for diameter, and how 'x' numbers work, means you're well on your way to truly understanding what a drawing is telling you about your رینگ اسپرت Û²Û°Û¶. It can be a little bit of a learning curve, but it's totally worth it for clear communication.

Getting the Depth Right for Your رینگ اسپرت ۲۰۶ Components

Imagine you're going through some practice examples, and you come across a diagram that shows a part, but you're not quite sure how to figure out its depth. You might have the part drawn up in a software like Inventor, which is great for visualizing things in three dimensions. However, sometimes the way depth is indicated on a flat, two-dimensional drawing can be, you know, a bit confusing. It's not always as straightforward as seeing a single number with an arrow.

Sometimes, depth might be implied by different views of the part, or it could be indicated by specific lines or notes that you need to piece together. For instance, you might see a projection from a top view to a side view, and the vertical distance between those projected lines would tell you the depth. Or there might be a callout that explicitly states the depth for a particular feature, like a pocket or a step. It's, basically, about looking at all the information presented and putting the puzzle pieces together to form a complete picture of the part's dimensions, especially when you're working on something as precise as a رینگ اسپرت ۲۰۶ component.

This kind of interpretation is, in some respects, a skill that develops with practice. The more diagrams you look at, the more familiar you become with the different ways designers communicate these three-dimensional aspects on a flat surface. Getting the depth right is, obviously, just as important as getting the diameter right, because if your part isn't the correct thickness or has a pocket that's too shallow or too deep, it simply won't fit or function properly in your رینگ اسپرت ۲۰۶ assembly. So, it's worth taking the time to truly understand how depth is being shown.

Making Parts for Your رینگ اسپرت ۲۰۶ Project with CNC

If you're just starting out in mechanical engineering, but you're already working on a project that you want to send off for CNC machining, that's, you know, a really cool step. CNC, or Computer Numerical Control, machines are amazing because they can create parts with incredible precision from your digital designs. However, when you're looking for services to manufacture your parts, you might find that different places have different requirements or ways of interpreting drawings, which can be, honestly, a bit of a hurdle at first.

Many services you find can make a wide range of parts, but it's up to you to provide them with drawings that are absolutely clear and unambiguous. This goes back to all those symbols and annotations we've been discussing. If your drawing isn't clear about a diameter, a depth, or a tolerance, the CNC service might have to guess, or worse, they might make the part incorrectly. So, ensuring your designs are perfectly understood is, basically, a very important part of the process, especially for your رینگ اسپرت ۲۰۶ components.

The better you are at reading and creating these technical drawings, the smoother the manufacturing process will be. It means fewer questions from the service provider, less chance of errors, and ultimately, getting the exact parts you need for your رینگ اسپرت ۲۰۶ project. So, even though you're new to mechanical engineering, focusing on clear communication through your drawings is, apparently, one of the best things you can do to ensure success with CNC machining.

Deciphering Screw Nut Dimensions for رینگ اسپرت ۲۰۶

Let's say you're trying to model some parts for your own custom 3D printer, which is, you know, a fantastic project. You might have found some flanged lead screw nuts that you plan to use, but then you hit a snag: you're having a really hard time reading the dimensions on their datasheet. This is a pretty common challenge because these components often have very specific measurements that need to be understood precisely for everything to fit and function correctly.

When you look at these dimensions, you might be pretty sure it has something to do with how the part fits into an assembly. It could possibly be specifying whether to use the minimum circumscribed circle or the maximum inscribed circle to tolerance the diameter. This sounds a bit technical, but what it really means is how much wiggle room or exactness is allowed for the roundness of the part. For a lead screw nut, getting this right is, obviously, critical for how smoothly the screw turns within it, which directly impacts the movement of your 3D printer, and by extension, your رینگ اسپرت ۲۰۶.

These kinds of tolerance specifications are, in fact, very important for ensuring that parts can be manufactured consistently and still fit together. A minimum circumscribed circle would be the smallest circle that can completely enclose the part, while a maximum inscribed circle is the largest circle that can fit entirely within the part. Understanding which

- Ifsa Sotwe Turk

- Froot Vtuber Cheating

- As The World Caves In Song Meaning

- Iran And Pakistan Map

- 124 Squid Game Death

Diameter Symbol (ø, Ø) - Copy and Paste Text Symbols - Symbolsdb.com

Diameter Ø Symbol Mathematical Notation Circle, PNG, 2000x2179px

Diameter symbol Ø - Autodesk Community