دکتر صداقت مشهد - Making Sense Of Technical Drawings

Imagine a world where the blueprints for incredible creations, like a new part for your 3D printer or a tiny component in a motor, spoke a language everyone could understand. For many, those detailed drawings with their lines, numbers, and strange symbols can feel a bit like reading ancient hieroglyphs. It's almost as if they hold secrets only a select few are allowed to know, and that can feel quite frustrating when you're trying to build something cool.

You see, these drawings are truly important. They tell us everything about how something should be made, from the size of a hole to the kind of material it needs. Without being able to read them, a lot of really neat ideas would just stay ideas, which is a shame, really. It’s like having a recipe but not being able to read the instructions, so you just stand there wondering what to do next, you know?

But what if there was someone who could help make these complicated drawings seem, well, a lot less scary? Someone who could help you look at a diagram and say, "Oh, I get that now!" That's where the work of people like دکتر صداقت مشهد comes in, offering a way to bridge that gap between the technical talk and what you need to actually do. It's about making things clearer, so you can go from just looking at a drawing to actually making something real.

- Denzel Washington Training Day

- 124 Squid Game Death

- Imskirby The Dog Incident

- Horses Mating

- Duck Dynasty The Wealth Of Willie Robertson

Table of Contents

- Biography - Who is دکتر صداقت مشهد?

- What Do Those Circles and Lines Mean on a Drawing?

- Reading Part Dimensions - Is it as Tricky as it Seems?

- Getting Your Designs Ready for Making - A Word from دکتر صداقت Ù…´Ù‡Ø¯

Biography - Who is دکتر صداقت Ù…´Ù‡Ø¯?

When we talk about making sense of complex technical things, the name دکتر صداقت Ù…´Ù‡Ø¯ often comes up as someone who truly helps people grasp what might otherwise seem quite difficult. This person has spent a good deal of time helping others see through the fog of technical language, making it easier for everyone to understand how things are put together or how they should be measured. You know, it's about taking something that looks like a puzzle and showing you where all the pieces fit, which is very helpful.

Their approach is, in a way, like having a friendly guide who walks you through a dense forest of information. Instead of just giving you a bunch of rules, they show you how those rules apply in real situations. For instance, when someone looks at a technical drawing and sees symbols they don't quite recognize, دکتر صداقت Ù…´Ù‡Ø¯ helps clear up that confusion. They focus on breaking down big, intimidating ideas into smaller, more manageable bits. This way, learning about things like precise measurements or how parts fit together becomes a much less intimidating experience, too it's almost like learning a new language, but with a great teacher.

A lot of their work seems to center on helping people who are just starting out in fields like mechanical engineering or those trying to build their own custom projects, like a 3D printer. They seem to have a knack for explaining things in a way that just clicks, helping folks avoid common mix-ups when reading drawings or planning for manufacturing. It’s not just about knowing the facts; it’s about knowing how to use them, and that, is that, a pretty big difference for many who are trying to make things work.

- Slang Eiffel Tower

- Daisys Destruction

- 1st Studio Siberian Mouse

- Lamar Jackson Injury History

- Bomb Iran Vince Vance

Personal Details of دکتر صداقت Ù…´Ù‡Ø¯

| Focus Area | Making Technical Information Accessible, Mechanical Drawing Interpretation, Precision Measurement |

| Approach | Simplifying Complex Concepts, Practical Application, Hands-on Guidance |

| Impact | Helps Learners and Practitioners Avoid Errors, Fosters Clearer Communication in Design and Manufacturing |

| Specialty | Clarifying Symbols and Annotations, Understanding Dimensions, Bridging Design to Production |

As you can see, the core of what دکتر صداقت Ù…´Ù‡Ø¯ does really revolves around clarity. They seem to be the kind of person who can look at a very busy drawing, full of numbers and odd marks, and tell you exactly what each part means in plain words. This focus on clear communication is really what makes their guidance so helpful for anyone who has ever felt lost trying to figure out a technical sheet. It’s about making sure that when you see a measurement for a stepper motor, you know precisely what it’s telling you, which is very important for building things correctly.

What Do Those Circles and Lines Mean on a Drawing?

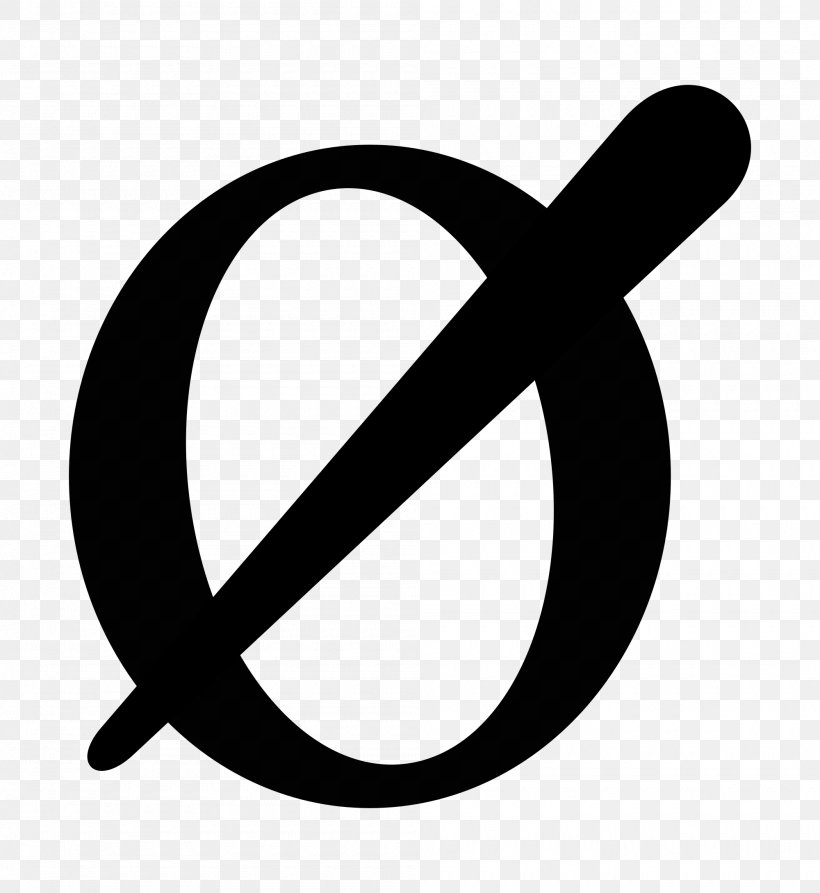

If you have ever looked at a technical drawing, you might have noticed some circles with slashes through them, or maybe some numbers next to letters like 'R'. These aren't just random decorations; they carry really specific messages about how a part should be shaped. For instance, you might see something like "ø6" next to a pinion on a stepper motor datasheet. This little symbol, the 'ø', is actually quite common and tells you about a circle's size, specifically its span across the middle. It's a way of being very precise about round things, you know?

Sometimes, this symbol might look a little different, like 'φ'. On a drawing for resistors, you might see "φ0.55mm" for the wire that sticks out. While 'ø' and 'φ' look a bit similar, and sometimes even get used in the same way, they both point to the idea of a circular measurement. The important thing is that they are giving you a specific size for something round. So, when you see these, you're not just looking at a pretty picture; you're getting exact instructions for how big something needs to be, which is very useful.

And what about those numbers that say something like "4x" before a measurement? That's actually a pretty straightforward way to save space and make a drawing easier to read. If you see "4x" before a specific size, it just means that measurement applies to four different spots on the drawing that look the same. So, if it says "4x ø5", it means there are four holes, and each one should be 5 millimeters across. It's a neat shorthand that helps keep the drawing from getting too cluttered, which is often a good thing when you're trying to figure out a design.

How Does دکتر صداقت Ù…´Ù‡Ø¯ Explain Diameter Symbols?

دکتر صداقت Ù…´Ù‡Ø¯ often points out that these symbols, like 'ø' or 'φ', are just quick ways to tell you about the size of a circular feature. They are basically saying, "Hey, this circle is this wide!" It's like a universal sign for "diameter," no matter where you are or what language you speak, which is pretty neat. So, when you see 'ø12' on a drawing for a plastic piece with an oval hole, you know that the circular part of that hole is 12 units across. It’s a very direct way to communicate a key measurement, which really helps prevent mistakes when you’re making something.

They also explain that sometimes, you'll see other bits of information tacked onto these measurements. For example, if you see something like "ø12 x25l", it means the hole is 12 units across, but then the "x25l" gives you more detail about its length or how far it goes. This extra information is crucial because it tells you the full story of that feature, not just its circular size. It’s like getting the full address instead of just the street name, which is often needed for precise work. دکتر صداقت Ù…´Ù‡Ø¯ emphasizes that paying attention to these small additions can save a lot of trouble down the line, as a matter of fact.

Another common annotation you might spot is something like "R1.25 typ" or "2xø1.0". دکتر صداقت Ù…´Ù‡Ø¯ would tell you that 'R' usually stands for 'radius', which is half of a diameter, so 'R1.25' means a curve with a sweep of 1.25 units. The 'typ' bit means it's a "typical" feature, so you might see it in other places on the drawing even if it's not explicitly marked everywhere. And "2xø1.0" is just another way of saying there are two holes, each one unit across. Basically, these are all just ways to be super clear about the shape and size of every little bit of a design, which is really important for getting things right.

Reading Part Dimensions - Is it as Tricky as it Seems?

When you're trying to build something, whether it's a custom 3D printer or a new mechanical device, getting the dimensions right is everything. It's one thing to see a number on a drawing, but it's another to know exactly what that number means for the part you're holding or trying to make. Sometimes, even simple-looking measurements can hide little details that are easy to miss if you're not used to them. For example, a datasheet for a stepper motor might list a "pitch diameter" for a pinion, and that needs a specific way of thinking about it, which is often a little different from just measuring with a ruler.

Then there are things like wire gauges. You might see a drawing say a wire is "24 swg" and also give a diameter like "0.55mm". Now, if you look up "24 swg", it might tell you the diameter is actually "0.559mm". This slight difference can sometimes make you wonder if you're reading things correctly or if there's a tiny mistake somewhere. It's these kinds of small but important details that can make reading dimensions feel a bit tricky at first. It's about understanding that sometimes, different ways of describing the same thing might have very slight variations, and knowing when those variations matter, which is often the case in precise work.

And what about those parts that have very specific ways they need to fit together? Like those flanged lead screw nuts you might use in a 3D printer. Reading their dimensions can be tough because they often involve how they interact with other components, not just their own standalone size. You might see terms that hint at how to "tolerance" a diameter, like using a "minimum circumscribed" or "maximum inscribed" circle. These are fancy ways of saying how much wiggle room a part has while still fitting properly. It's about ensuring that even with slight differences from manufacturing, parts will still work as intended, which is quite clever when you think about it.

What About Special Notes Like "Thru All" for دکتر صداقت Ù…´Ù‡Ø¯?

دکتر صداقت Ù…´Ù‡Ø¯ would likely tell you that notes like "thru all" are simple but very important. When you see a hole marked with "ø5 thru all", it means that hole, which is 5 millimeters across, goes all the way through the piece. It sounds simple, but this note actually removes the need for another measurement that would tell you how deep the hole is. So, instead of having to specify a depth, "thru all" just means it goes from one side to the other. It's a clear and concise way to give a full instruction without adding extra numbers that might clutter the drawing, you know?

They also point out that understanding these notes is a big part of getting your designs ready for actual making. If you're sending a design to a CNC service for machining, or trying to model parts for your own 3D printer, every little annotation matters. For instance, if you have an oval hole, and the drawing says "ø12 x25l", you need to know that the 'x25l' isn't just random letters. It's probably telling you the length of the oval, or perhaps how far the oval extends. دکتر صداقت Ù…´Ù‡Ø¯ would stress that these extra bits of information are crucial for the people who will actually make your part, as they tell them exactly how to cut or shape the material, which is very important for the final product.

When you're new to mechanical engineering, these details can feel a bit overwhelming, but دکتر صداقت Ù…´Ù‡Ø¯ encourages people to see them as a kind of puzzle. Each symbol and note gives you a piece of the picture. For example, if you're trying to figure out the depth of a part from a diagram, sometimes the answer isn't a single number but comes from understanding how different features relate to each other, combined with notes like "thru all." It's about putting all the clues together to get a full picture of the part, which is pretty satisfying when you finally figure it out.

Getting Your Designs Ready for Making - A Word from دکتر صداقت Ù…´Ù‡Ø¯

For anyone who designs parts, whether for a hobby or for a job, the goal is always to get that design made into something real. This means your drawings need to be super clear for whoever is going to manufacture them. Many services that make parts, like those offering CNC machining or 3D printing, rely entirely on the information you provide in your drawings. If there's any confusion, even a small one, it can lead to parts that don't fit, or worse, parts that just can't be made as you intended. It's a bit like writing a recipe; if you leave out a key ingredient or a step, the dish just won't turn out right, you know?

دکتر صداقت Ù…´Ù‡Ø¯ often talks about the importance of being precise in your designs. They might explain that when you're modeling parts for something like a custom 3D printer, every single dimension you put into your software, like Inventor or AutoCAD, needs to be spot on. If you're using specific components, like those flanged lead screw nuts, you really need to be able to read their dimension sheets perfectly. It's not just about drawing a circle; it's about drawing a circle that is exactly the right size and in the right place, so it fits with everything else. This level of detail is what separates a working part from one that just sits on your desk, which is often the difference between success and frustration.

Ultimately, the guidance offered by people like دکتر صداقت Ù…´Ù‡Ø¯ helps bridge the gap between an idea on paper and a physical object. They help you understand that every line, every symbol, and every number on a technical drawing is there for a reason. It's all part of a very specific language that, once learned, opens up a whole new world of making and creating. So, the next time you look at a drawing with a 'ø' or a 'thru all' note, you can feel a little more confident that you know what it means, and that, is that, a pretty good feeling.

This article looked at how دکتر صداقت Ù…´Ù‡Ø¯ helps people understand complex technical drawings. We explored their approach to making difficult concepts easier to grasp. We also talked about common symbols like the diameter sign (ø or φ) and what they mean on a drawing. We then went into how to read different part dimensions, including those for stepper motors and lead screw nuts. Finally, we covered the importance of special notes like "thru all" and how all this information helps get designs ready for manufacturing, like with CNC services or 3D printing.

- Ludwig Bulge

- Thanos Actor Age Squid Game

- Squirrel Girl Punk Skin

- Is Riley Green A Republican Or Democrat

- Asianbunnyx Leaks

Diameter Symbol (ø, Ø) - Copy and Paste Text Symbols - Symbolsdb.com

Diameter Ø Symbol Mathematical Notation Circle, PNG, 2000x2179px

Diameter symbol Ø - Autodesk Community