خسرو صادق نیت - Making Sense Of Technical Drawings

Sometimes, you just look at a technical drawing, and it feels like a whole different language, doesn't it? You might have a data sheet for something like a stepper motor, and you see numbers with symbols that don't quite make immediate sense. It's a common feeling, that bit of confusion when you're trying to figure out what a specific measurement, say, the pitch diameter of a pinion listed as ø6, actually means for your project.

There are these little marks and figures on engineering plans, and honestly, figuring out what they are trying to tell you can be a bit of a puzzle. It's not just about seeing a number; it's about getting to grips with the symbols, the abbreviations, and the little notes that are there to guide you. You might, for instance, be looking at a resistor's details, where the lead diameter is given as φ0.55mm, and then you see it also mentions 24 swg, which is a wire size that measures 0.559mm across. So, you're left wondering, is that a small difference, or is there something else going on?

It turns out, a lot of people face these kinds of questions when they are just starting out, or even when they've been doing this for a while. It's about getting comfortable with the way things are written down in the world of mechanical plans. You want to be sure you're reading everything just right, so your parts fit, or your designs work the way they should. This whole area, you know, can feel a little bit like learning a new secret code, but it's really about getting familiar with the common ways these details are put down on paper.

- Himynamestee Only Fans

- Is Riley Green A Republican Or Democrat

- Dafina Miftari

- Was The Shah Of Iran A Good Leader

- Unveiling The Charisma Of John Stamos Young

Table of Contents

- What Do Those Little Circles Mean?

- Getting a Handle on Material Specifications and خسرو صادق نیت

- Decoding Drawing Annotations – Is That a Hole or Just a Mark?

- Understanding Depth and Other Tricky Measurements with خسرو صادق نیت

- Navigating New Territory in Mechanical Design

- Putting Together 3D Printer Parts and خسرو صادق نیت

- Tolerances and How They Shape Your Pieces

- The Path to Clearer Understanding

What Do Those Little Circles Mean?

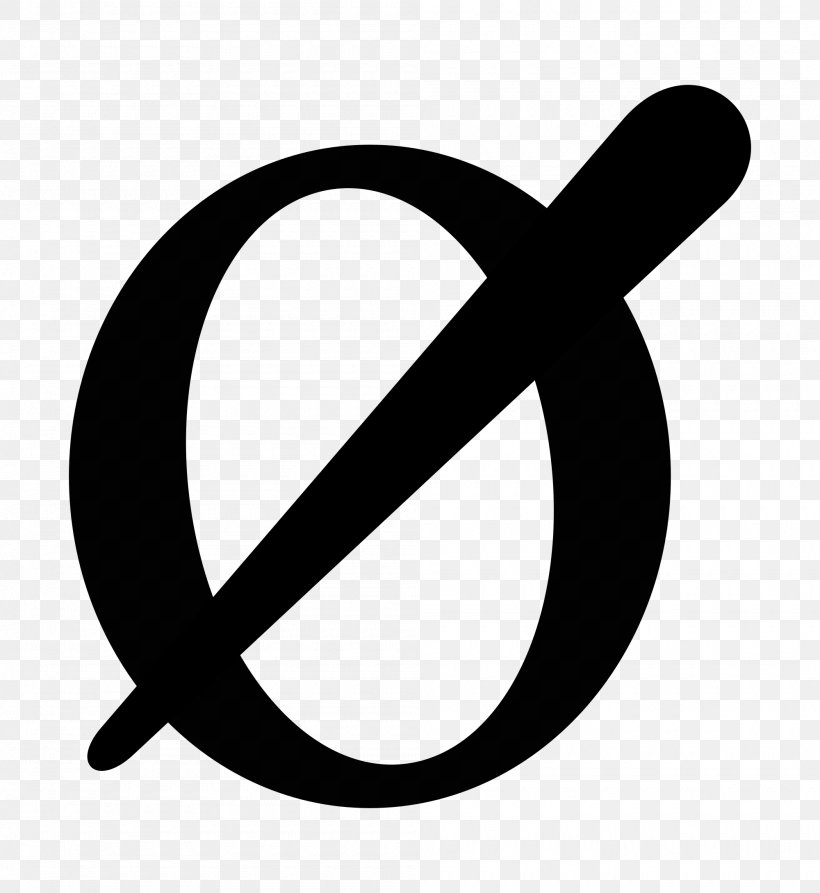

You know, it's almost like a universal language, but sometimes it needs a little translation. When you see a symbol like ø or φ on a drawing, you are pretty much looking at something that tells you about the size across a circular shape. For instance, on a data sheet for a stepper motor, you might see the pitch diameter of a small gear, often called a pinion, listed as ø6. This simply means that the distance across that circular gear is 6 millimeters. It's a very common way to show circular sizes, and you'll see it a lot on all sorts of plans, you know, for different parts and pieces.

Then there's the whole business with the symbol itself. Looking at a place like Wikipedia, it seems the little circle with a line through it, ø, is often used for diameter. It's a pretty straightforward way to show that measurement. But then you also have the diameter symbol (⌀), which is a Unicode character (u+2300), and it looks quite similar to the lowercase letter ø. In some writing styles, they might even look exactly the same, which can be a little confusing, but in many others, they are drawn a bit differently. It's really just about recognizing that both of these are pointing to the same idea: the measurement from one side of a circle to the other, going right through the middle.

So, when you see ø5, for example, it means that the hole's measurement across, its drill size, is 5mm. It's a pretty direct way to give that information, and it's something you get used to seeing quite quickly. These symbols are there to give you a clear picture of the physical size of circular parts, whether it's a shaft, a hole, or a gear. They are, in a way, the shorthand for telling you how wide something round is, which is pretty useful when you're trying to make things fit together.

- Sophie Rain Leaked Nudes

- Discovering The Multitalented Max Minghella An Artistic Journey

- Aishah Sofey Leak Free

- Lamar Jackson Injury History

- Daisys Destruction

Getting a Handle on Material Specifications and خسرو صادق نیت

Sometimes, when you're looking at the details for something like resistors, you might find the lead diameter given as φ0.55mm. Then, right alongside it, they might also mention that the wire is 24 swg. Now, if you look up 24 swg, which is a standard wire gauge, you'll find that its measurement across is 0.559mm. So, you're left with a tiny difference: 0.55mm versus 0.559mm. This can make you pause and wonder, is that small variation important, or is it just a rounding thing? It's a good question to ask, especially when you are trying to be very precise with your work. Getting a handle on these tiny differences is part of the process, and understanding how they relate to the bigger picture of خسرو صادق نیت, or clear communication in drawings, is key.

It's not uncommon to see these kinds of small discrepancies, and often, it comes down to how measurements are rounded or what level of precision is truly needed for that particular piece. For some things, a difference of a few hundredths of a millimeter might not matter at all, but for others, it could be absolutely critical. This is where you might need to look at the overall context of the part and what it's going to be used for. Is it a component that needs to fit very snugly, or is there a bit of wiggle room? These details are usually pretty important for making sure everything works as intended, and sometimes, you might even need to ask someone who knows a bit more about the specific standards being used.

The whole idea of material specifications, like wire gauges, is that they provide a common reference point. When a drawing specifies something like 24 swg, it's giving you a standard size that people in the industry recognize. This helps make sure that when parts are made, they are made to the right dimensions, even if there's a slight difference in how a specific drawing might list a measurement. It's all part of making sure that everyone is on the same page when it comes to the physical properties of the materials being used, which, you know, is pretty important for getting things right.

Decoding Drawing Annotations – Is That a Hole or Just a Mark?

When you're looking at an AutoCAD drawing, or really any technical drawing, you'll see little notes and symbols all over the place. These are called annotations, and they are there to give you extra information about the parts. For example, you might see "4 x" next to a feature. This simply means that whatever that feature is, it applies to four separate instances on the drawing that look similar. So, if there's a hole, and it says "4 x" next to it, that means there are four identical holes somewhere on that piece. It's a pretty efficient way to avoid drawing the same detail over and over again, and it helps keep the drawing from getting too cluttered, which is nice.

Then there are phrases like "thru all" that you might come across. This is often added next to a hole measurement, like "Ø 5 thru all." What this tells you is that the hole, which measures 5mm across, goes all the way through the material. It removes the need for a separate note about the depth of the hole, making it clear that it punches right through the entire piece. It's a very common shorthand in mechanical drawings, and it saves a lot of space and makes the drawing easier to read quickly. These little phrases are, in some respects, just shortcuts that convey a lot of information without using too many words, which is pretty clever.

You'll also see things like "R1.25 typ" (for a circle or hole on the left), "2xø1.0" (for a circle or hole on the right), and "ø1.25" (for a circle or hole at the bottom). Let's break those down a little. "R1.25 typ" means that the radius of that curve or hole is 1.25 units, and "typ" means "typical," suggesting that other similar features on the drawing might have the same radius, even if not explicitly noted. "2xø1.0" means there are two holes, each measuring 1.0mm across. And "ø1.25" is just a straightforward diameter of 1.25mm for that particular feature. These annotations are, you know, the way engineers communicate the precise details of a part, and getting comfortable with them is a big step in understanding the drawings, which is part of the larger challenge of خسرو صادق نیت.

Understanding Depth and Other Tricky Measurements with خسرو صادق نیت

When you are going through practice examples, you might come across a diagram and find yourself wondering how to figure out the depth of a particular part. It's a common sticking point, especially when you're just starting out in mechanical design. You might have the part drawn up in a software program like Inventor, but then looking at the 2D diagram, it's not always immediately clear how far a certain feature extends into or out of the material. This is where understanding the different views on a drawing, like top, front, and side views, becomes really important. They each give you a piece of the puzzle, and you need to put them together to get a full picture of the part's three-dimensional shape, which is a big part of getting a handle on خسرو صادق نیت.

Sometimes, the depth might be explicitly noted, perhaps with a dimension line pointing to it, or a cross-section view might be provided to show the internal features and their depths. But other times, you might need to infer it from other measurements or from how different features line up across different views. For instance, if you have a hole, and it doesn't say "thru all," there should be a separate depth callout or a view that shows how deep that hole goes. It's a bit like being a detective, you know, gathering clues from various parts of the drawing to build a complete mental model of the object.

Then there's the situation with unusual shapes, like a plastic piece that has an oval hole. You might understand that the ø12 part of the measurement is for a diameter, but then you see something like "x25l" at the end, and you're not quite sure what that indicates. This kind of annotation can be a little tricky because it's not always a standard symbol. It could be specifying the length of the oval, or it might be a custom notation used by that particular company or designer. In such cases, if you can't find a legend or another clue on the drawing, it might be necessary to ask for clarification. It's pretty important to get these things right, especially if you're planning to have the part machined, so you don't end up with something that's not quite what you had in mind.

Navigating New Territory in Mechanical Design

Being somewhat new to mechanical engineering can feel like stepping into a whole new world, especially when you're working on a project that you eventually want to send off to a CNC service for machining. You've got these designs, and you want them to come to life, but the process of getting them made involves understanding a lot of specific details on the drawings. Many services you find can manufacture a wide range of parts, but their ability to do so accurately really depends on how clearly and correctly your plans are drawn up. It's a little bit like writing instructions for someone else to build something; every detail has to be just right, or they might end up making something different from what you intended.

The transition from designing on a computer to getting a physical piece in your hand involves a lot of communication through these technical drawings. You're trying to model a few parts, perhaps for your own custom 3D printer, and you've found some flanged lead screw nuts that you plan to use. But then, you're having a hard time reading the dimensions on their data sheets. This is a very common hurdle. The way dimensions are presented can vary, and sometimes the drawings might be less clear than you'd like. It's pretty crucial to be able to interpret these accurately, because even a small misreading can lead to parts that don't fit together or don't perform as they should. This is where the challenge of خسرو صادق نیت really comes into play.

So, you're not alone in facing these challenges. Everyone who gets into mechanical design or manufacturing has to go through this learning curve. It involves getting familiar with the different ways dimensions are shown, what all the symbols mean, and how to spot potential ambiguities. It's a skill that builds over time with practice and exposure to different types of drawings. The more you look at them, the more you model parts, and the more you interact with services that make these parts, the better you get at it. It's a continuous learning process, and every drawing you interpret adds to your understanding.

Putting Together 3D Printer Parts and خسرو صادق نیت

When you're working on building something like a custom 3D printer, you're pretty much assembling a collection of very specific components. You might have already found some flanged lead screw nuts that you are going to use, which is a great start. But then comes the part where you need to look at their dimension drawings, and that's where things can get a little bit tough. Reading these detailed plans for off-the-shelf parts can be quite a challenge, especially if you're not used to all the different ways measurements are presented. You need to know exactly how big each part is, what its features are, and how it's supposed to connect with other pieces. This is where the quest for clarity, which is خسرو صادق نیت in a sense, becomes very important.

For instance, you might be looking at a drawing and see various numbers and symbols that indicate lengths, widths, and depths. But then there are also things like chamfers, fillets, and specific hole patterns that need to be understood. If you misinterpret even one of these, the part you design to connect with it might not fit correctly. It's a bit like trying to put together a puzzle where some of the pieces have very detailed instructions that you need to follow precisely. You have to make sure your own modeled parts will align perfectly with the parts you've purchased, and that means getting every measurement just right.

Sometimes, the drawings provided by manufacturers can be a little bit sparse, or they might use symbols or notations that are specific to their own internal standards. This can add another layer of difficulty. You might find yourself searching online for explanations of certain symbols or trying to compare the drawing to a physical part if you have one. It's all part of the process of making sure that your custom build comes together smoothly and that all the mechanical elements work in harmony. It's a very rewarding feeling when everything clicks into place, and that really starts with being able to read those drawings with confidence.

Tolerances and How They Shape Your Pieces

You know, when you're dealing with precise parts, it's not just about the main measurement; it's also about how much wiggle room, or tolerance, is allowed. You might be pretty sure that a particular note on a drawing has something to do with how a part fits, possibly specifying whether to use the minimum circumscribed circle or the maximum inscribed circle to control the diameter. This is a pretty important concept in manufacturing because no part can ever be made absolutely perfectly to a single measurement. There's always a tiny bit of variation, and tolerances tell you how much variation is acceptable for a part to still function as it should. It's a very critical aspect of ensuring that pieces made by different machines or at different times will still fit together correctly.

For example, if you have a shaft that needs to fit into a hole, the drawing won't just give you one size for the shaft and one for the hole. It will give you a range for each. The "minimum circumscribed circle" and "maximum inscribed circle" are ways to define the boundaries of that acceptable range for circular features. Basically, they help ensure that a shaft won't be too big to fit into a hole, and a hole won't be too small for a shaft to go through. It's a subtle but powerful way to control how parts interact, and it's something that experienced engineers spend a lot of time getting just right. This level of detail is very much part of what makes خسرو صادق نیت so important.

Understanding these tolerance concepts is pretty essential if you're designing parts that need to assemble precisely, or if you're sending your designs to a manufacturer. They rely on these tolerance specifications to know how accurately they need to make the part. If you don't specify tolerances, or if you specify them incorrectly, you might end up with parts that don't fit, or that cost too much to produce because they're being made more precisely than they need to be. It's all about finding that sweet spot where the parts function well without being overly expensive to create, which is a key part of practical engineering.

The Path to Clearer Understanding

So, you've got this data sheet for a stepper motor, and you're trying to figure out the pitch diameter of the pinion, which is listed as ø6. You're also looking at the Wikipedia page for ø to get a better grasp of what that symbol means. Then there's the technical drawing for resistors, where the lead diameter is φ0.55mm, and you're comparing it to the 24 swg wire, which is 0.559mm, wondering about the slight difference. You're also trying to understand what "4 x" means on a drawing, or that "Ø 5" means a 5mm hole, and "thru all" removes the need for extra depth notes. It's all part of the journey to becoming more comfortable with technical drawings.

- Fiona Gallagher Shameless

- Agentredgirl

- Ludwig Bulge

- Sophie Rain Leaked Nudes

- Tails Comic Two Babies One Fox

Diameter Symbol (ø, Ø) - Copy and Paste Text Symbols - Symbolsdb.com

Diameter Ø Symbol Mathematical Notation Circle, PNG, 2000x2179px

Diameter symbol Ø - Autodesk Community