الن دی جنرس - Decoding Engineering Drawings

For anyone who has ever looked at a technical drawing and felt a little lost, you're certainly not by yourself. Those sheets, full of lines and symbols, can seem like a secret language, especially if you're just starting out in the world of making things. It's a bit like trying to read a map without knowing what all the little pictures mean. Yet, these drawings hold all the vital clues for creating something real, whether it's a tiny part for a printer or a piece of machinery. You know, getting a handle on them really opens up a lot of possibilities.

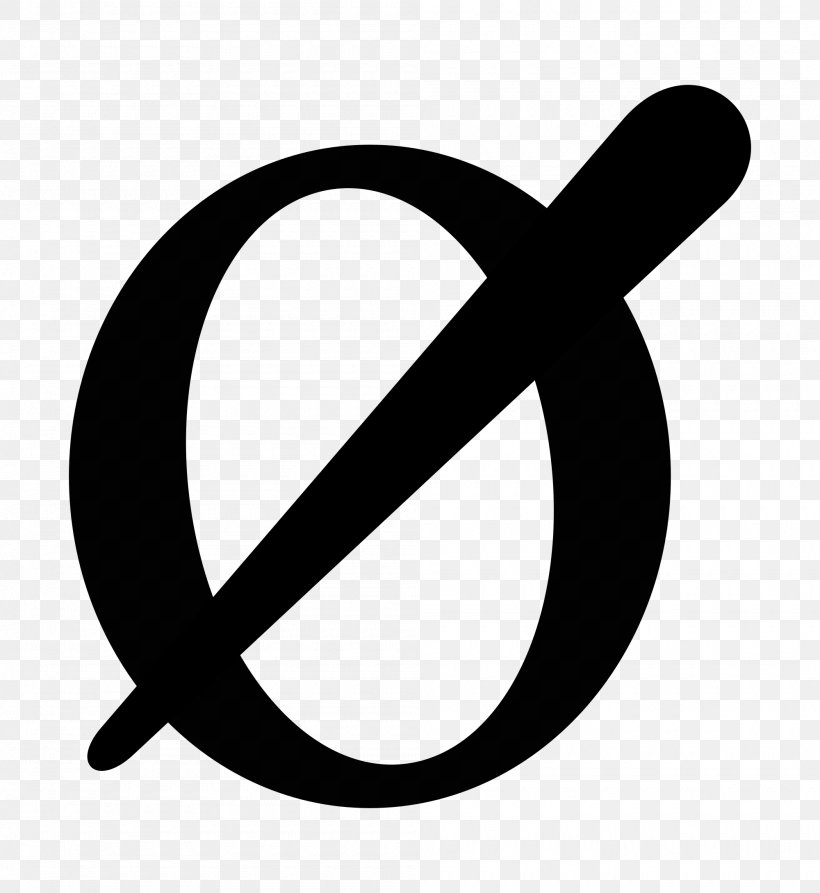

It's honestly quite common for folks to wonder about the tiny marks or the specific ways numbers appear on a blueprint. Perhaps you've seen a circle with a line through it, or maybe a number followed by an 'x' and then more letters, and just thought, "What in the world is that trying to tell me?" We've all been there, scratching our heads over what might seem like small details but actually carry a lot of weight for the people who build things. It's truly about finding the simple explanations behind what looks complex.

The good news is that these symbols and notations aren't meant to confuse you; they're actually there to make things very clear and precise. Once you get a feel for what each mark means, those drawings become much friendlier. We're going to take a look at some of these common questions people have about technical drawings, helping you feel more at ease with them, especially as you think about making your own projects come to life. So, you might just find it's easier than you thought.

- Net Worth Of Jojo Siwa

- 1st Studio Siberian Mouse

- Is Emily Compagno Married

- Sophie Rain Leaked Nudes

- Iran And Pakistan Map

Table of Contents

- What Do Those Circles Mean?

- How Do We Read Measurements Like 'x25l'?

- Are All Holes The Same?

- What About Wire Sizes and Resistor Details?

- Getting Parts Made - What's Important?

What Do Those Circles Mean?

When you look at a drawing for something mechanical, like a part for a stepper motor, you'll often see a circle with a line going through it. This little mark, you know, looks a bit like the letter 'ø' or sometimes 'φ'. People often wonder what it's all about. Well, this symbol is a very simple way to show you a diameter. It tells you the distance straight across a round object or a hole. For instance, if you see 'ø6' next to a small gear, it means the measurement across that gear's pitch line is 6 units. It's just a quick way to get that information across.

You might even notice that the symbol used on drawings, the one that tells you a diameter, can look pretty similar to the lowercase letter 'ø' that you see in some languages. In fact, some fonts use the exact same picture for both. Yet, in other fonts, they look a little different. It's actually a specific character, called unicode character U+2300, but its closeness to the letter 'ø' can sometimes cause a tiny bit of confusion for someone just learning the ropes. So, it's good to keep that in mind.

Understanding Diameter Symbols for الن دی جنرس

Getting comfortable with these diameter symbols is pretty important for anyone working with technical drawings, especially if you're part of what we might call الن دی جنرس – the folks who are building the things of tomorrow. When a drawing shows 'ø5', for example, it's telling you the hole needs to be 5 millimeters across. This is really about the size of the drill bit you'd pick to make that hole. It's a very direct instruction, you see, making sure everyone involved knows exactly what size is needed for that particular opening.

- Riley Green Political Party

- %D9%83%D9%85 %D8%A7%D9%84%D9%85%D8%B3%D8%A7%D9%81%D8%A9 %D8%A8%D9%8A%D9%86 %D8%A7%D9%8A%D8%B1%D8%A7%D9%86 %D9%88%D8%A7%D8%B3%D8%B1%D8%A7%D8%A6%D9%8A%D9%84

- Many Summers Later Gravity Falls

- Emily Compagno Children

- Unveiling The Charismatic Actor From Mad Men A Journey Through Talent And Fame

Sometimes, these symbols come with other numbers or notes. You might see something like '2xø1.0'. This means there are two holes, and each one needs to be 1.0 units across. Or, perhaps, 'ø1.25' just tells you one hole is 1.25 units across. These simple notations are actually quite powerful because they give very clear instructions without needing a lot of extra words. It helps to make sure that parts fit together just right, which is, honestly, a big part of making anything work well. It's a way to be very precise.

How Do We Read Measurements Like 'x25l'?

Sometimes, on a drawing for a plastic piece, you might see a measurement like 'ø12 x25l' for an oval hole. You get that 'ø12' means the diameter of the round part of the hole is 12. But then, what's with the 'x25l' at the end? It's a common question, and it really points to how drawings can combine information in a compact way. This extra bit usually tells you something more about the shape or the extent of that feature. It's a way, you know, to give a fuller picture of the part's shape.

In many cases, the 'x' here doesn't mean multiplication in the usual math sense. Instead, it acts as a separator or a way to link different parts of a dimension. The '25l' could mean the length of the oval part is 25, or it might refer to a specific type of length measurement, like a length along an axis. It's all about providing the exact details needed to shape that oval opening correctly. So, you're basically getting two pieces of information about one feature in a single line, which is quite efficient.

Making Sense of Complex Dimensions for الن دی جنرس

For those of us trying to make sense of these detailed drawings, especially as we move into what we call الن دی جنرس of design and manufacturing, understanding these combined dimensions is a big step. When you see '4 x' on a drawing, for example, it means that whatever dimension follows applies to four similar spots on the drawing. It's a handy shortcut, you know, so the drafter doesn't have to write out the same information four separate times. It saves space and makes the drawing cleaner.

Another thing you might come across is a note about a 'minimum circumscribed' or 'maximum inscribed' circle when it comes to tolerancing a diameter. This is a bit more involved, but basically, it's about how much wiggle room there is for a part's size to be off and still fit correctly. It's honestly about making sure that even with slight differences from one manufactured piece to another, they will still work as intended. This kind of detail is pretty important for parts that need to fit together very snugly, or perhaps, move smoothly.

Are All Holes The Same?

You might see a note like "thru all" added to a hole's dimension on a drawing. This little phrase is actually very important, and it helps to remove any doubt about how deep a hole should be. When a hole is marked "thru all," it means that the hole goes completely through the entire thickness of the part. It's not just a partial hole or a blind hole that stops partway through. This is a very clear instruction, you know, so there's no guessing involved in the workshop.

Without "thru all," someone might wonder if the hole should stop at a certain depth, or if it's meant to go all the way through. Adding this note makes it absolutely clear. It's a simple phrase, yet it carries a lot of meaning for anyone trying to make the part. It ensures that the person doing the drilling or machining knows exactly what's expected, which can save a lot of time and prevent mistakes. So, it's a very helpful piece of information.

The 'Thru All' Idea for الن دی جنرس

For those of us getting ready for الن دی جنرس of manufacturing, where precision is often key, understanding these small but mighty notes is really quite something. When a drawing for a stepper motor or a plastic piece says "thru all" for a hole, it’s like giving a definite instruction. It means the hole passes completely through the material, from one side to the other. This clarity helps to prevent issues later on, ensuring the part functions as it should, perhaps by allowing a bolt to pass all the way through.

This kind of clear communication on a drawing is, honestly, a big part of successful making. It helps everyone involved, from the person designing the part to the person operating the machinery, to be on the same page. It means less guesswork and more accurate production, which is always a good thing. So, a simple phrase like "thru all" actually makes a very significant difference in how a part is made and how it will perform.

What About Wire Sizes and Resistor Details?

When you're looking at a technical drawing for something electrical, like resistors, you might see details about wire sizes. For example, a drawing might specify the lead diameter of a resistor as 'φ0.55mm'. That 'φ' symbol, similar to the 'ø' we talked about, also means diameter. It's telling you how thick the wire coming out of the resistor is. This is pretty important for making sure the resistor fits into a circuit board or connects properly. You know, every tiny bit matters.

What's interesting is when they also tell you the wire is '24 swg'. 'SWG' stands for Standard Wire Gauge, which is another way to measure wire thickness. If 24 SWG means a diameter of 0.559mm, and the drawing says 'φ0.55mm', you might wonder why there's a tiny difference. This could be due to manufacturing tolerances, or perhaps the drawing is giving an ideal measurement while the SWG is a standard that's very close. It's a good example of how you sometimes need to compare different pieces of information to get the full picture, honestly.

Connecting Electrical Parts to الن دی جنرس

Understanding these specific details, like wire gauges and lead diameters, is very much a part of getting ready for الن دی جنرس of electronic assembly. Knowing that a resistor's wire is 'φ0.55mm' and also '24 swg' helps you confirm that you're using the right components. It ensures that the parts you pick will fit where they need to go and carry the right amount of electricity without issues. It's a bit like making sure all the pieces of a puzzle are the correct shape and size, you know.

This attention to detail helps prevent problems down the line, whether you're building a custom 3D printer or any other electronic device. It means fewer reworks and more reliable finished products. So, even these small numbers and symbols on a drawing are pretty important for making sure everything works as it should. It's all about precision, really, and getting things right from the start.

Getting Parts Made - What's Important?

If you're new to mechanical engineering and working on a project you want to send to a CNC service for machining, or perhaps you're modeling parts for a custom 3D printer, reading these drawings correctly is super important. You might have found some flanged lead screw nuts you plan to use, but then you have a hard time understanding the dimensions on their datasheet. This is a common hurdle, you see, and it really highlights why knowing these symbols matters so much.

Many services that make parts rely entirely on the information you give them on a drawing. If the drawing isn't clear, or if you've misunderstood a symbol, the part might not come out the way you expect. For instance, if you're trying to figure out the depth of a part from a diagram, every line and number gives a clue. It's like putting together a puzzle where each piece of information helps you build the full picture of the object. So, clarity in your drawing is honestly a big deal.

Preparing for CNC and 3D Printing for الن دی جنرس

For those stepping into the manufacturing world, especially with tools like CNC machines and 3D printers that are part of الن دی جنرس of making, accurate drawings are your best friend. When you send a file to a CNC service, they take your drawing very literally. If your drawing has 'R1.25 typ' for a circle or hole on the left, '2xø1.0' for one on the right, and 'ø1.25' for one at the bottom, they will make it exactly that way. It's their instruction manual, you know.

Being able to read and create clear drawings means your parts will turn out right the first time. This saves you time, money, and a lot of frustration. It's about translating your idea into a language that machines can understand, which is a pretty cool thing when you think about it. So, getting comfortable with these drawing details is truly a valuable skill for anyone looking to bring their designs into the physical world.

We've looked at how those circle symbols tell us about diameters, how combined measurements like 'x25l' give us more shape details, and why a simple phrase like "thru all" is so important for holes. We also touched on how wire sizes are shown and why paying attention to them helps, especially when picking parts for things like 3D printers. And, you know, we talked about how clear drawings are key when you're getting parts made by a service. It's all about making sure everyone understands the plan for building things, from the smallest gear to a custom machine.

- Aishah Sofey Onlyfans Leaked

- Emily Compagno Children

- Himynamestee Only Fans

- 69069 Text

- Many Summers Later Gravity Falls

Diameter Symbol (ø, Ø) - Copy and Paste Text Symbols - Symbolsdb.com

Diameter Ø Symbol Mathematical Notation Circle, PNG, 2000x2179px

Diameter symbol Ø - Autodesk Community